Nkọwa

Njirimara ihe owuwu

● Ihe ndị na-eme nrụgide na-eji ígwè alloy dị elu na ike dị mma na mmetụta siri ike.

● Ọnụ ụzọ nke nrụgide dị elu BOP na-eji akara jikọtara ọnụ, nke nwere akara dị mma site na nrụgide olulu mmiri.

● Jiri ọnụ ụzọ na-ese n'elu mmiri ma ọ bụ integral, nwere ike mechie nke ọma wee gbanwee nke ọma.

● Jiri ụzọ mmanụ dị ka olili ozu, kewapụrụ ihe nrịba ama na nhịahụ hydraulic.

● Ọdịdị hinge dị mfe, dị mfe ịkwatu na ịrị elu.

● Jiri nnukwu shei ụdị arc dị n'akụkụ abụọ nke ọnụ ụlọ ahụ, na-ebugharị site n'ụdị arc gburugburu, iji belata nrụgide kacha elu nke shea ahụ n'okpuru nrụgide.

● N'ụdị kọmpat, dị obere karịa ngwaahịa mba ọzọ yiri ya.

● Ihe dị n'ime shei nke BOP na-eguzogide obere okpomọkụ nwere ike ịhazi pipeline, iji mee ka uzuoku na-asọba n'ime BOP, na-ekpo ọkụ.

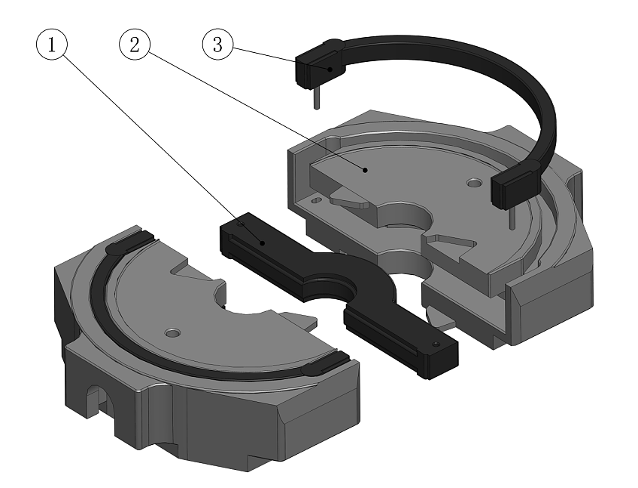

Mgbakọ Ram

● Pipe Ram

| |

| 1. Top akara 2. N'ihu akara 3. Ram ahu | 1. Ram ahụ 2. Bolt 3. Ram bolt 4. Ram roba 5. Ihe njide |

| HF ụdị Ram assembl | S ụdị Ram assembl |

| | |

| |

| 1. Ala shear ram body 2. Top akara rọba 3. Right akara rọba 4. Blade sealLeft akara rọba 3. Up shiee ebule ahụ elu 4. Top akara roba 5. Left akara rọba 6. Up shiee ebule ahụ | |

| Shear Ram Mgbakọ Structure nke S ụdị Ram BOP | |

Ram dị iche iche

Enwere ike iji ebule dị iche iche mechie dayameta dị iche iche nke eriri ọkpọkọ.Ebulu na-agbanwe agbanwe bụ ebule agbanwe, akara n'elu, akara n'ihu na-agbanwe agbanwe.Ntinye nke ebule agbanwe na BOP dị ka ebule nkịtị, ọ dịghị mkpa ịgbanwe akụkụ ọ bụla nke BOP.

| |||||||||

| Nrụgide arụ ọrụ (psi) | gbara (n'ime) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | |||||||||

| 105-15000 | S | S | S | S | |||||

| 70-10000 | S | S | S | S | S | ||||

| 35-5000 | S | S | S | S | S | S | S | ||

| 21-3000 | S | S | S | S | S | S | S | ||

| 14-2000 | S | ||||||||

Mara: S Ram BOP Specification&Model

S na-anọchi anya S ụdị ebule BOP

| Nkọwapụta & Nlereanya | Isi Bore mm(n'ime) | Nrụgide arụ ọrụ MPa (psi) | Ọnụ ọgụgụ mmanụ maka imeghe (Single Silinder) | Ọnụ ọgụgụ mmanụ maka mmechi (Single Silinder) | Ụdị Ram | Nha Ram (n'ime) | Akụkụ mm | ibu n'arọ | Koodu BOP akwadoro | |||||

| ogologo | obosara | elu | otu | okpukpu abụọ | ||||||||||

| otu | okpukpu abụọ | |||||||||||||

| 180 (71/16 na) usoro | (2)FZ18-21 | 179.4 (71/16) | 21-3000 | 1.6 | 2 | H | kacha5 9/16 | 1420 | 645 | 568 | 854 | 855 | 1540 | (2) S04.00 |

| (2)FZ18-35 | 179.4 (71/16) | 35-5000 | 1.6 | 2 | H | kacha5 9/16 | 1420 | 645 | 624 | 910 | 895 | 1580 | (2) S48.00 | |

| (2)FZ18-70 | 179.4 (71/16) | 70-10000 | 2.2 | 2.5 | H | kacha5 9/16 | 1720 | 640 | 897 | 1262 | 1660 | 3020 | (2) S62.00 | |

| (2)FZ18-105 | 179.4 (71/16) | 105-15000 | 7.4 | 8 | H | kacha 5 1/2 | 1988 | 820 | 922 | 1372 | 3175 | 5885 | (2) S29.00A | |

| 230(9in) usoro | (2)FZ23-21 | 228.6-9 | 21-3000 | 1.3 | 1.5 | HF | kacha 7 | 1526 | 565 | 580 | 866 | 705 | 1250 | (2) S79.00 |

| (2)FZ23-35 | 228.6-9 | 35-5000 | 4.7 | 5.3 | HF | kacha 7 | 2036 | 720 | 805 | 1190 | 1830 | 3415 | (2) S23.00 | |

| (2)FZ23-70 | 228.6-9 | 70-10000 | 7 | 8 | H | kacha 7 | 2324 | 850 | 1038 | 1518 | 3635 | 6835 | (2) S01.00 | |

| (2)FZ23-105 | 228.6-9 | 105-15000 | 10.2 | 10.9 | HF | kacha 7 | 2170 | 920 | 1140 | 1640 | 4150 | 7500 | (2) S93.00 | |

| 280 (11in) usoro | (2)FZ28-21 | 279.4-11 | 21-3000 | 2.7 | 3.2 | S | kacha 8 5/8 | 1846 | 675 | 740 | 1100 | 1400 | 2550 | (2) S77.00 |

| (2)FZ28-35 | 279.4-11 | 35-5000 | 5.4 | 6.2 | S | kacha 8 5/8 | 2265 | 785 | 895 | 1325 | 2475 | 4550 | (2) S45.00 | |

| (2)FZ28-70 | 279.4-11 | 70-10000 | 7 | 8 | H | kacha 8 5/8 | 2324 | 850 | 1102 | 1582 | 3770 | 6850 | (2) S16.00 | |

| (2)FZ28-105 | 279.4-11 | 105-15000 | 14.6 | 16.7 | H | kacha 8 5/8 | 2650 | 1050 | 1244 | 1784 | 6303 | 11028 | (2) S67.00 | |

| 346 (135/8 na) usoro | (2)FZ35-21 | 346.1 (135/8) | 21-3000 | 7.8 | 8.9 | S | kacha 10 3/4 | 2414 | 760 | 774 | 1164 | 2705 | 5115 | (2) S78.00 |

| (2)FZ35-35 | 346.1 (135/8) | 35-5000 | 7.9 | 9.3 | S | kacha 10 3/4 | 2415 | 847 | 930 | 1370 | 3010 | 5480 | (2) S103.00 | |

| (2)FZ35-70 | 346.1 (135/8) | 70-10000 | 18 | 20.7 | HF | kacha 10 3/4 | 2786 | 1085 | 1276 | 1782 | 6120 | 11135 | (2) S104.00 | |

| (2)FZ35-105 | 346.1 (135/8) | 105-15000 | 17.4 | 20 | H | kacha 10 3/4 | 3074 | 1140 | 1420 | 1985 | 8945 | 16070 | (2) S115.00 | |

| 425 (163/4 nke anụ ọhịa) | (2)FZ43-35 | 425.5 (163/4) | 35-5000 | 10.3 | 11.6 | HF | kacha 10 3/4 | 2923 | 1190 | 1090 | 1570 | 5300 | 9860 | (2) S95.00 |

| 476 (183/4 na) usoro | (2)FZ48-35 | 476.3 (183/4) | 35-5000 | 24.5 | 27.9 | HF | kacha 16 | 3430 | 1440 | 1504 | 2072 | 9758 | 12286 | (2) S116.00 |

| (2)FZ48-70 | 476.3 (183/4) | 70-10000 | 24.5 | 27.9 | HF | kacha 16 | 3430 | 1440 | 1618 | 2186 | 10312 | 20624 | (2) S102.00 | |

| 527 (203/4 nke anụ ọhịa) | (2)FZ53-21 | 527.1 (203/4) | 21-3000 | 12.2 | 13.6 | HF | kacha 16 | 3424 | 1165 | 1065 | 1650 | 6130 | 13355 | (2) S83.00 |

| 540 (211/4 na) usoro | (2)FZ54-14 | 539.8 (211/4) | 14-2000 | 12.1 | 13.8 | HF | kacha 16 | 3300 | 1130 | 940 | 1480 | 5560 | 10200 | (2) S33.00 |

| (2)FZ54-35 | 539.8 (211/4) | 35-5000 | 26 | 29.6 | HF | kacha 16 | 3590 | 1445 | 1320 | 1950 | 9270 | 17670 | (2) S105.00 | |

| 680 (263/4 nke anụ ọhịa) | (2)FZ68-21 | 679.5 (263/4) | 21-3000 | 32.6 | 37 | HF | kacha 18 5/8 | 4350 | 1450 | 1250 | 1870 | 12360 | 20290 | (2) S87.00 |

| Mara:1.Nnwale BOP bụ ugboro 1.5 nke nrụgide ọkọlọtọ | ||||||||||||||

| 2. Nrụgide arụ ọrụ sitere na 8.4Mpa ruo 10.5Mpa | ||||||||||||||

S Type Shear Ram nkọwapụta arụmọrụ

| Ụdị BOP | Ụdị BOP | Koodu BOP akwadoro | Ụdị Silinder | Nkọwapụta ọkpọkọ ọkpọkọ |

| S | (2) FZ 18-70 | (2) S62.00 | Silinda nkịtị | |

| (2) S92.00 | Cylinder nwere ihe nkwalite tandem | 4 1/2" 16.6lb/ft G-105 PSL-3 | ||

| (2) FZ28-35 | (2) S45.00 | Nnukwu cylinder | ||

| (2) S100.00 | Nnukwu cylinder | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 28-70 | (2) S16.00 | Silinda nkịtị | ||

| (2) S02.00 | Nnukwu cylinder | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-35 | (2) S103.00 | Silinda nkịtị | ||

| (2) S99.00 | Nnukwu cylinder | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-70 | (2) S104.00 | Silinda nkịtị | 5" 19.5lb/ft G-105 PSL-3 | |

| (2) S112.00 | Nnukwu cylinder | 5 1/2" 24.7lb/ft G-105 PSL-3 | ||

| (2) S117.00 | Cylinder nwere ihe nkwalite tandem | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2) FZ 35-105 | (2) S115.00 | Silinda nkịtị | 5" 19.5lb/ft G-105 PSL-3 | |

| (2) S113.00 | Cylinder nwere ihe nkwalite tandem | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2) FZ 54-35 | (2) S105.00 | Silinda nkịtị | 5" 19.5lb/ft G-105 PSL-3 |

S Ụdị mgbanwe Ram Range

| Ụdị BOP | Ụdị BOP | Oke nke Ram agbanwe agbanwe (n'ime) | |||

| S | (2) FZ 18-70 | 2 3/8"-3 1/2" | |||

| (2) FZ28-35 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2) FZ 28-70 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2) FZ 35-35 | 2 3/8-3 1/2 | 2 7/8"-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-70 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-105 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 53-21 | 4 1/2 "-5 1/2" | ||||

| (2) FZ 54-14 | 4 1/2 "-5 1/2" | ||||

| (2) FZ 54-35 | 4 1/2 "-5 1/2" | ||||

Akụrụngwa arụrụ arụ nwere tọn 160, tọn 300, tọn 400, tọn 630, tọn 1000, tọn 1600 na tọn 2500, nwere ike imepụta gram iri ruo kilogram 55 nke ngwaahịa adịchaghị mma.

Ngwongwo eji eme ihe nwere lathe, igwe na-egwuputa ihe, igwe ihe, ịkpụ waya, CNC na ihe ndị ọzọ.

ọgwụgwọ okpomọkụ gụnyere normalizing, tempering, annealing, quenching, siri ike ngwọta, carburizing, wdg

Ngwọta dị n'elu gụnyere ịgba agba agba, eserese ịgba, electroplating, electrophoresis, phosphate na ndị ọzọ

Ngwa nnwale ahụ gụnyere spectrometer, metallographic analyzer, mita ike, igwe tensile, igwe nnwale mmetụta, fluorescent particle flaw detector, ultrasonic flaw detector, atọ nhazi, wdg.

A na-eji ngwaahịa eme ihe na ụlọ ọrụ petrochemical, igwe injinia, akụkụ ụgbọ ala, akụkụ ụgbọ oloko na akụkụ ụgbọ oloko, ọla, nrụpụta ụgbọ mmiri, ngwaahịa ndị agha na mpaghara ndị ọzọ.

Ndị otu R&D na-eduzi imewe CAD, CAM, UG, SOLIDWORKS ụdị ọrụ.

Anyị na-eji superfine die steels dị ka akụrụngwa, na-enye ohere ka ejiri CNC center hazie ya, na-ahụ na a na-ahụta nkenke nke nchara anwụ anwụ ma nwee nguzogide ike ọgwụgwụ dị mma, nguzogide abrasive, na-ejide n'aka na a na-emepụta forgings dị elu.

Enwere ihe karịrị 2000 tent nke ebu ebe a na ụlọ ọrụ anyị.Ndị ahịa nwere ike ịhọrọ nke ọ bụla n'ime ha maka nhazi iji belata ọnụ ahịa.Anyị na-ewere ngwaahịa, na-ekpochapụ na ndekọ kwa izu iji hụ na mmepụta ahụ na-aga n'ihu dị ka emebere ya.

A na-ejikwa ụlọ nkwakọba ihe akpụ akpụ anyị site n'ịgbaso usoro njikwa àgwà IATF16949 na "6S lean management", na-enye ndụ ogologo ndụ na ebu ma mee ka ọ dị mfe iji na nchekwa.

Anyị ga-emepụta ma rụpụta akpụ akpụ na nnata nke ndị ahịa eserese ma ọ bụ samples, mgbe ahụ, anyị ga-arụpụta ebu site na-eso ebu imewe.Ihe ndị na-akpụ akpụ na-agụnyekarị anwụ anwụ, igbutu anwụ.

Mbelata billet ígwè na kpo oku

Ọtụtụ mgbe, anyị ga-akwadebe ihe ndị a na-ejikarị eme ihe na ngwaahịa na-egosi ihe nke 20 #, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q235,105te, mgbe ahụ, otu ugboro, Q345, wdg. A ga-eji ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ n'ime ụfọdụ okpomọkụ na n'ikpeazụ tinye mkpanaka iri nri n'elu ígwè e ji arụ ọrụ.

Na-akpụ akpụ

Tupu usoro nhazi igwe amalite, elu na ala nwụrụ ga-ejikọta ya na ngọngọ nke igwe nrụpụta.Mgbe ahụ, ndị ọrụ ga-eburu ihe ndị ahụ ígwè ma tinye ha n'etiti anwụ anwụ na-eme ka ha nweta ọdịdị a chọrọ site na ịpị ihe ígwè ọtụtụ ugboro na ngwa ngwa.

Nhicha

Mgbe emechara aghụghọ ahụ, a ga-enwe ihe ndị a na-achọghị na gburugburu oghere ndị a rụrụ arụ, yabụ iwepụ ihe ndị ahụ bụ nzọụkwụ dị mkpa.Nke na-achọ ka ndị ọrụ na-ebugo trimming nwụrụ n'okpuru ebe a na-akụ ọkpọ, wee pịa oghere ndị ahụ adịgboroja iji hichaa burrs n'elu nke forgings.

Ọgwụgwọ okpomọkụ

Usoro ọgwụgwọ okpomọkụ na-enyere aka nweta ọrụ arụ ọrụ achọrọ na ike nke ngwaahịa.Usoro ọgwụgwọ okpomọkụ na-ekpuchi normalizing, quenching, annealing, tempering, hardening and so on.

Mgbawa agbawa

Mgbe usoro ịgbawa agbawa agbachara, akpụ akpụ ahụ ga-adị nro ma dị ọcha karịa ka ọ gaara adị.A na-enwekarị ire ụtọ elu nke forgings na Ra6.3, nke na-adịkwa nro karịa nke nkedo na-efunahụ.

Nhazi

Maka akụkụ ụfọdụ, usoro ịgha mkpụrụ adịghị na nnabata achọrọ, n'okpuru nke a, nhazi bụ nhọrọ.Anyị ga-eduzi nhazi ngwaahịa na ngwa nhazi dị iche iche, gụnyere igwe igwe igwe, igwe na-agwụ ike, igwe na-egwupụta ihe, igwe na-egweri, igwe njikwa ọnụọgụ wdg.

Ọgwụgwọ elu

N'ọtụtụ ọnọdụ, ọ bụrụ na ọnweghị ihe achọrọ kpọmkwem, anyị ga-enweta ọgwụgwọ nchebe mmiri / mmanu nchara n'elu nke forgings.Anyị nwekwara ike iduzi ọgwụgwọ ndị ọzọ dị n'elu, gụnyere ịgba agba agba, mkpuchi ntụ ntụ, electroplating, electrocoating iji gboo mkpa ndị ahịa anyị.

Nyocha ikpeazụ

Anyị ga-enwe nyocha na nha ngwaahịa ahụ iji hụ na ngwaahịa anyị dị elu. Mgbe ụfọdụ, anyị na-enwekwa ọrụ arụ ọrụ na akụrụngwa kemịkalụ na-anwale ngwaahịa anyị.

Ngwugwu na nnyefe

Ọtụtụ mgbe, a ga-etinye ihe ndị a kpụrụ akpụ n'ime akpa polyethylene wee tinye ya n'ime igbe osisi siri ike.Anyị nwekwara ike hazie ngwugwu dịka mkpa ndị ahịa si dị.Dịka anyị nọ na ogige mmepụta ihe nke Ruian forgings, anyị na-enweta ngwa ngwa ngwa ngwa, nke na-efu ọnụ n'ozuzu ya.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu