Katrangan

Fitur Struktural

● komponen meksa adopts baja alloy unggul karo kekuatan apik lan impact kateguhan.

● Door segel saka dhuwur meksa BOP nggunakake segel gabungan, kang wis segel luwih saka meksa sumur.

● Gunakake ngambang utawa gapura integral, bisa segel aman lan ngganti nduweni.

● Gunakake buriel-jinis wacana lenga, Engsel bantalan dipisahake saka hinge hydraulic.

● Struktur engsel prasaja, gampang dicopot lan dipasang.

● Gunakake cangkang busur-jinis amba ing loro-lorone saka kamar, lan transit dening busur-jinis kabeh watara, kanggo ngurangi kaku puncak Nihan ing meksa.

● Kanthi struktur kompak, luwih cilik tinimbang produk manca sing padha.

● Nihan internal BOP tahan kanggo suhu kurang bisa proses pipo, kanggo nggawe aliran uap nang BOP, radiat panas.

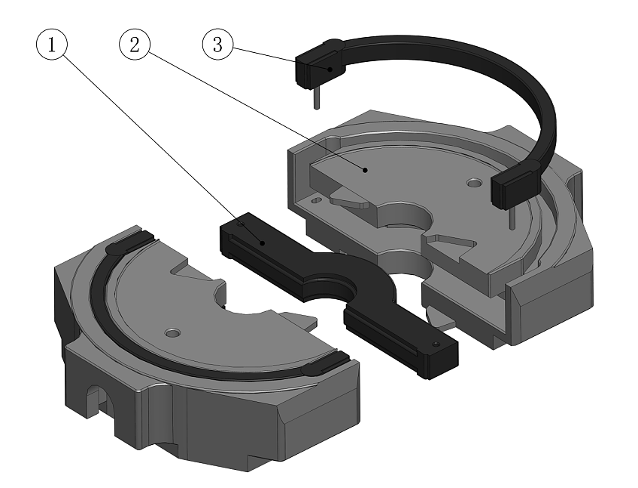

Majelis Ram

● Ram Pipa

| |

| 1. Top segel 2. Front segel 3. Ram awak | 1. Ram body 2. Bolt 3. Ram bolt 4. Ram karet 5. nduwèni Clamp |

| HF jinis Ram ngrakit | Ram tipe S |

| | |

| |

| 1. Karet segel mudhun 2. Karet segel ndhuwur 3. Karet segel tengen 4. Segel blade karet segel kiwa 3. Badan segel munggah 4. Karet segel ndhuwur 5. Karet segel kiwa 6. Awak ram geser munggah | |

| Struktur Rakitan Ram Geser saka Ram BOP tipe S | |

Variabel Ram

Variabel ram bisa digunakake kanggo segel diameteripun beda saka senar pipe.Ram variabel dumadi saka ram variabel, segel ndhuwur, segel ngarep variabel.Instalasi ram variabel ing BOP padha karo ram umum, ora perlu ngganti bagean BOP.

| |||||||||

| Tekanan operasi (psi) | Bore (ing) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | |||||||||

| 105-15000 | S | S | S | S | |||||

| 70-10000 | S | S | S | S | S | ||||

| 35-5000 | S | S | S | S | S | S | S | ||

| 21-3000 | S | S | S | S | S | S | S | ||

| 14-2000 | S | ||||||||

Cathetan:S Ram BOP Spesifikasi & Model

S nggantosi S jinis ram BOP

| Spesifikasi & Model | Bore Utama mm (ing) | Tekanan Kerja MPa (psi) | Jumlah lenga kanggo bukaan (Silinder Tunggal) | Jumlah lenga kanggo nutup (Silinder Tunggal) | Tipe Ram | Ukuran Ram (ing) | Ukuran mm | bobote kg | Kode BOP sing disaranake | |||||

| dawa | ambane | dhuwur | tunggal | pindho | ||||||||||

| tunggal | pindho | |||||||||||||

| 180 (71/16 in) seri | (2) FZ18-21 | 179.4(71/16) | 21-3000 | 1.6 | 2 | H | maksimal5 9/16 | 1420 | 645 | 568 | 854 | 855 | 1540 | (2)S04.00 |

| (2) FZ18-35 | 179.4(71/16) | 35-5000 | 1.6 | 2 | H | maksimal5 9/16 | 1420 | 645 | 624 | 910 | 895 | 1580 | (2)S48.00 | |

| (2) FZ18-70 | 179.4(71/16) | 70-10000 | 2.2 | 2.5 | H | maksimal5 9/16 | 1720 | 640 | 897 | 1262 | 1660 | 3020 | (2)S62.00 | |

| (2)FZ18-105 | 179.4(71/16) | 105-15000 | 7.4 | 8 | H | maksimal5 1/2 | 1988 | 820 | 922 | 1372 | 3175 | 5885 | (2)S29.00A | |

| 230 (9in) seri | (2) FZ23-21 | 228.6-9 | 21-3000 | 1.3 | 1.5 | HF | maksimal 7 | 1526 | 565 | 580 | 866 | 705 | 1250 | (2)S79.00 |

| (2) FZ23-35 | 228.6-9 | 35-5000 | 4.7 | 5.3 | HF | maksimal 7 | 2036 | 720 | 805 | 1190 | 1830 | 3415 | (2)S23.00 | |

| (2)FZ23-70 | 228.6-9 | 70-10000 | 7 | 8 | H | maksimal 7 | 2324 | 850 | 1038 | 1518 | 3635 | 6835 | (2)S01.00 | |

| (2)FZ23-105 | 228.6-9 | 105-15000 | 10.2 | 10.9 | HF | maksimal 7 | 2170 | 920 | 1140 | 1640 | 4150 | 7500 | (2)S93.00 | |

| 280 (11in) seri | (2)FZ28-21 | 279.4-11 | 21-3000 | 2.7 | 3.2 | S | maksimum 8 5/8 | 1846 | 675 | 740 | 1100 | 1400 | 2550 | (2)S77.00 |

| (2) FZ28-35 | 279.4-11 | 35-5000 | 5.4 | 6.2 | S | maksimum 8 5/8 | 2265 | 785 | 895 | 1325 | 2475 | 4550 | (2)S45.00 | |

| (2)FZ28-70 | 279.4-11 | 70-10000 | 7 | 8 | H | maksimum 8 5/8 | 2324 | 850 | 1102 | 1582 | 3770 | 6850 | (2)S16.00 | |

| (2)FZ28-105 | 279.4-11 | 105-15000 | 14.6 | 16.7 | H | maksimum 8 5/8 | 2650 | 1050 | 1244 | 1784 | 6303 | 11028 | (2)S67.00 | |

| 346 (135/8 in) seri | (2) FZ35-21 | 346.1(135/8) | 21-3000 | 7.8 | 8.9 | S | maksimum 10 3/4 | 2414 | 760 | 774 | 1164 | 2705 | 5115 | (2)S78.00 |

| (2) FZ35-35 | 346.1(135/8) | 35-5000 | 7.9 | 9.3 | S | maksimum 10 3/4 | 2415 | 847 | 930 | 1370 | 3010 | 5480 | (2)S103.00 | |

| (2)FZ35-70 | 346.1(135/8) | 70-10000 | 18 | 20.7 | HF | maksimum 10 3/4 | 2786 | 1085 | 1276 | 1782 | 6120 | 11135 | (2)S104.00 | |

| (2)FZ35-105 | 346.1(135/8) | 105-15000 | 17.4 | 20 | H | maksimum 10 3/4 | 3074 | 1140 | 1420 | 1985 | 8945 | 16070 | (2)S115.00 | |

| 425 (163/4 in) | (2) FZ43-35 | 425.5(163/4) | 35-5000 | 10.3 | 11.6 | HF | maksimum 10 3/4 | 2923 | 1190 | 1090 | 1570 | 5300 | 9860 | (2)S95.00 |

| 476 (183/4 in) seri | (2) FZ48-35 | 476.3(183/4) | 35-5000 | 24.5 | 27.9 | HF | maksimal 16 | 3430 | 1440 | 1504 | 2072 | 9758 | 12286 | (2)S116.00 |

| (2)FZ48-70 | 476.3(183/4) | 70-10000 | 24.5 | 27.9 | HF | maksimal 16 | 3430 | 1440 | 1618 | 2186 | 10312 | 20624 | (2)S102.00 | |

| 527(203/4in) | (2)FZ53-21 | 527.1(203/4) | 21-3000 | 12.2 | 13.6 | HF | maksimal 16 | 3424 | 1165 | 1065 | 1650 | 6130 | 13355 | (2)S83.00 |

| 540 (211/4 in) seri | (2)FZ54-14 | 539.8(211/4) | 14-2000 | 12.1 | 13.8 | HF | maksimal 16 | 3300 | 1130 | 940 | 1480 | 5560 | 10200 | (2)S33.00 |

| (2)FZ54-35 | 539.8(211/4) | 35-5000 | 26 | 29.6 | HF | maksimal 16 | 3590 | 1445 | 1320 | 1950 | 9270 | 17670 | (2)S105.00 | |

| 680(263/4in) | (2) FZ68-21 | 679.5(263/4) | 21-3000 | 32.6 | 37 | HF | maksimum 18 5/8 | 4350 | 1450 | 1250 | 1870 | 12360 | 20290 | (2)S87.00 |

| Cathetan: 1.Tekanan BOP Testing yaiku 1,5 kaping tekanan standar | ||||||||||||||

| 2. Tekanan operasi saka 8.4Mpa nganti 10.5Mpa | ||||||||||||||

S Type Shear Ram Spesifikasi Operasi

| Tipe BOP | Model BOP | Kode BOP sing disaranake | Tipe Silinder | Spesifikasi Pipa Bor |

| S | (2) FZ 18-70 | (2)S62.00 | Silinder normal | |

| (2)S92.00 | Silinder karo tandem booster | 4 1/2" 16,6lb/ft G-105 PSL-3 | ||

| (2) FZ28-35 | (2)S45.00 | Silinder gedhe | ||

| (2)S100.00 | Silinder gedhe | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 28-70 | (2)S16.00 | Silinder normal | ||

| (2)S02.00 | Silinder gedhe | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-35 | (2)S103.00 | Silinder normal | ||

| (2)S99.00 | Silinder gedhe | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-70 | (2)S104.00 | Silinder normal | 5" 19.5lb/ft G-105 PSL-3 | |

| (2)S112.00 | Silinder gedhe | 5 1/2" 24,7lb/ft G-105 PSL-3 | ||

| (2)S117.00 | Silinder karo tandem booster | 5 1/2" 24,7lb/ft S-135 PSL-3 | ||

| (2)FZ 35-105 | (2)S115.00 | Silinder normal | 5" 19.5lb/ft G-105 PSL-3 | |

| (2)S113.00 | Silinder karo tandem booster | 5 1/2" 24,7lb/ft S-135 PSL-3 | ||

| (2) FZ 54-35 | (2)S105.00 | Silinder normal | 5" 19.5lb/ft G-105 PSL-3 |

S Tipe Variabel Ram Range

| Tipe BOP | Model BOP | Range Variabel Ram (ing) | |||

| S | (2) FZ 18-70 | 2 3/8" - 3 1/2" | |||

| (2) FZ28-35 | 2 3/8" - 3 1/2" | 3 1/2"-5" | |||

| (2) FZ 28-70 | 2 3/8" - 3 1/2" | 3 1/2"-5" | |||

| (2) FZ 35-35 | 2 3/8-3 1/2 | 2 7/8"-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-70 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2)FZ 35-105 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 53-21 | 4 1/2" - 5 1/2" | ||||

| (2) FZ 54-14 | 4 1/2" - 5 1/2" | ||||

| (2) FZ 54-35 | 4 1/2" - 5 1/2" | ||||

Peralatan penempaan nduweni 160ton, 300 ton, 400 ton, 630 ton, 1000 ton, 1600 ton, lan 2500 ton, bisa nggawe sepuluh gram nganti 55 kilogram produk penempaan kasar utawa presisi.

Peralatan mesin duwe bubut, mesin pengeboran, gilingan, pemotong kawat, CNC lan liya-liyane.

Perawatan panas kalebu normalisasi, tempering, anil, quenching, larutan padat, carburizing, lsp

Perawatan lumahing kalebu shot blasting, lukisan semprotan, electroplating, elektroforesis, fosfat lan liya-liyane

Peralatan pengujian kalebu spektrometer, penganalisa metalografi, meter kekerasan, mesin tarik, mesin uji dampak, detektor cacat partikel magnetik fluoresensi, detektor cacat ultrasonik, telung koordinat, lsp.

Produk digunakake akeh ing industri petrokimia, mesin teknik, suku cadang mobil, bagian lokomotif lan sepur, metalurgi, galangan kapal, produk militer lan lapangan liyane.

Tim R&D nindakake karya modeling CAD, CAM, UG, SOLIDWORKS.

Kita nggunakake baja mati superfine minangka bahan mentahan, saéngga bisa diproses kanthi pusat CNC, mesthekake presisi baja die dijamin lan nduweni resistensi lemes banget, resistensi abrasif, nggawe manawa forgings diprodhuksi kanthi kualitas dhuwur.

Ana luwih saka 2000 set cetakan ing perusahaan kita.Pelanggan bisa milih salah sijine kanggo diproses kanggo nyuda biaya.We nindakake persediaan njupuk, ngresiki lan ngrekam saben minggu kanggo mesthekake yen produksi neruske minangka dijadwal.

Warehouse cetakan kita dikelola kanthi ngetutake sistem manajemen kualitas IATF16949 lan "manajemen ramping 6S", menehi umur layanan sing dawa kanggo jamur lan nggawe trep kanggo panggunaan lan panyimpenan.

Kita bakal ngrancang lan nggawe cetakan forging nalika nampa gambar utawa conto pelanggan, banjur kita bakal nggawe cetakan kanthi ngetutake desain cetakan.Cetakan asring kalebu forging dies, trimming dies.

Pemotongan billet baja lan pemanasan

Asring, kita bakal nyiapake bahan sing asring digunakake ing saham sing nampilake materi No. 20#, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q4535, lan frekuensi intermediate 42CrMo, Q4535, lan liya-liyane. tungku bakal digunakake kanggo dadi panas bahan mentahan menyang suhu tartamtu lan pungkasanipun sijine rod mangan ing framework logam kanggo forging.

Forging

Sadurunge proses penempaan logam diwiwiti, mati ndhuwur lan ngisor kudu disambungake menyang blok anvil penempaan.Banjur para pekerja bakal milih bahan logam lan dilebokake ing antarane cetakan kanggo entuk bentuk sing dikarepake kanthi mencet bahan logam kaping pirang-pirang kanthi kacepetan dhuwur.

Reresik

Sawise tempa rampung, bakal ana burr sing ora dikarepake ing saubengé kosong palsu, saéngga mbusak burr minangka langkah sing perlu.Kang mbutuhake buruh kanggo Gunung trimming mati ing punching penet, banjur mencet blanks palsu kanggo ngresiki burrs ing lumahing forgings.

perawatan panas

Proses perawatan panas mbantu entuk kinerja mekanik lan kekerasan produk sing dibutuhake.Teknik perawatan panas kalebu normalisasi, quenching, annealing, tempering, hardening lan liya-liyane.

Ditembak blasting

Sawise proses blasting dijupuk, forgings bakal duwe lumahing Gamelan lan resik saka iku bakal wis.Biasane Gamelan lumahing forgings kasedhiya ing Ra6.3, kang malah Gamelan saka casting ilang-lilin.

Ngolah

Kanggo sawetara komponen, proses forging ora kasedhiya ing toleransi sing dibutuhake, ing kasus iki, pangolahan opsional.Kita bakal nindakake pangolahan produk kanthi peralatan pangolahan sing beda-beda, kalebu mesin penggilingan, mesin bor, penet pengeboran, mesin penggiling, mesin kontrol numerik lsp.

Pangobatan lumahing

Umume kasus, yen ora ana syarat khusus, kita bakal duwe perawatan proteksi karat banyu / minyak ing permukaan tempa.Kita uga bisa nindakake perawatan lumahing liyane, kalebu Paint uyuh, powder coating, electroplating, electrocoating kanggo nyukupi kabutuhan tartamtu saka pelanggan.

Ujian pungkasan

Kita bakal mriksa ukuran produk kanggo njamin kualitas produk kita. Kadhangkala, kita uga duwe pengujian kinerja mekanik lan komponen kimia ing produk kita.

Paket lan pangiriman

Umume kasus, komponen palsu bakal dibungkus ing tas poliethelin lan banjur dilebokake ing kothak kayu sing kuat.Kita uga bisa ngatur paket miturut kabutuhan pelanggan.Minangka kita dumunung ing Ruian forgings industri park, kita duwe akses gampang kanggo sumber bahan baku, kang biaya efektif ing kabèh.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu