Motokari yekubatanidza tsvimbo ndiyo yepakati yekubatanidza tsvimbo mune yemukati inopisa tsvimbo, uye batanidza piston kune crankshaft, kuitira kuti igadzire meshini inofambisa simba kubva papiston kuenda ku crankshaft, ipapo kune kutapurirana.Mushure mekunge tsvimbo yekugadzira yapera, tinosarudza zvinhu zvakasiyana-siyana uye nzira dzekugadzira kuti tive nechokwadi chemhando.Kazhinji, tsvimbo yekubatanidza inogadzirwa nekabhoni simbi, ine mari yekukanda, kudonhedza forging uye poda metallurgy zvese zvakanaka zvekugadzira maitiro sarudzo.

Forged simbi yekubatanidza matanda anowanikwa kune akasiyana einjini dzedhiziri, kuve nechokwadi chekuti tsvimbo yekubatanidza inoshanda.

Mhinduro: Injini yemotokari

zvinhu: SAE1035

Kururamisa: ± 0.01mm

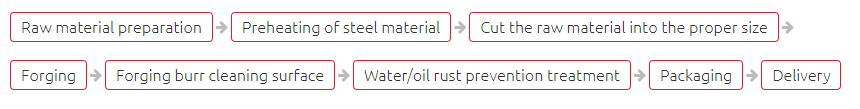

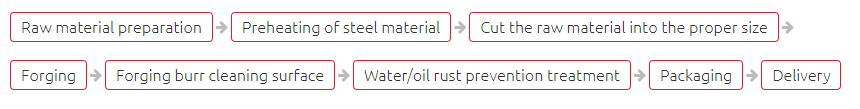

Nzira yekugadzira

Raw zvinhu zvinonyanya zvinosanganisira kabhoni simbi, alloy simbi, Stainless simbi, aruminiyamu, uye mhangura, nezvimwewo, zvinowanzoshandiswa zvinhu 45#, Q235, Q345, 35Mn, 65Mn, 40Cr, 35CrMo, 42CrMo, 4140, 20CrM0Cr, 20CrM04, 20CrM04, 310, 316, 431, Al, Mhangura, nezvimwe.

Raw zvinhu zvinonyanya zvinosanganisira kabhoni simbi, alloy simbi, Stainless simbi, aruminiyamu, uye mhangura, nezvimwewo, zvinowanzoshandiswa zvinhu 45#, Q235, Q345, 35Mn, 65Mn, 40Cr, 35CrMo, 42CrMo, 4140, 20CrM0Cr, 20CrM04, 20CrM04, 310, 316, 431, Al, Mhangura, nezvimwe.

Midziyo yekuforoma ine 160tons, 300 tons, 400 tons, 630 tons, 1000 tons, 1600 tons, and 2500 tons, inogona kugadzira magiramu gumi kusvika ku55 kilograms yezvakakasharara zvekufogisa kana kunyatso forging zvigadzirwa.

Machining emidziyo ine lathe, muchina wekuchera, grinder, waya yekucheka, CNC uye zvichingodaro.

Kurapa kwekupisa kunosanganisira kujaira, kudziya, kuvhara, kudzima, mhinduro yakasimba, carburizing, nezvimwe.

Kurapa kwepamusoro kunosanganisira kuputika kwepfuti, kupuruzira pendi, electroplating, electrophoresis, phosphate uye zvichingodaro

Midziyo yekuyedza inosanganisira spectrometer, metallographic analyzer, kuoma mita, tensile muchina, kukanganisa kuyedza muchina, fluorescent magnetic particle flaw detector, ultrasonic flaw detector, matatu anoronga, nezvimwe.

Zvigadzirwa zvinoshandiswa zvakanyanya muindasitiri yepetrochemical, mainjiniya muchina, auto zvikamu, locomotive uye njanji zvikamu, metallurgy, shipbuilding, zvigadzirwa zvemauto nemimwe minda.

Forged simbi yekubatanidza matanda anowanikwa kune akasiyana einjini dzedhiziri, kuve nechokwadi chekuti tsvimbo yekubatanidza inoshanda.

Mhinduro: Injini yemotokari

zvinhu: SAE1035

Kururamisa: ± 0.01mm

Nzira yekugadzira

Raw zvinhu zvinonyanya zvinosanganisira kabhoni simbi, alloy simbi, Stainless simbi, aruminiyamu, uye mhangura, nezvimwewo, zvinowanzoshandiswa zvinhu 45#, Q235, Q345, 35Mn, 65Mn, 40Cr, 35CrMo, 42CrMo, 4140, 20CrM0Cr, 20CrM04, 20CrM04, 310, 316, 431, Al, Mhangura, nezvimwe.

Raw zvinhu zvinonyanya zvinosanganisira kabhoni simbi, alloy simbi, Stainless simbi, aruminiyamu, uye mhangura, nezvimwewo, zvinowanzoshandiswa zvinhu 45#, Q235, Q345, 35Mn, 65Mn, 40Cr, 35CrMo, 42CrMo, 4140, 20CrM0Cr, 20CrM04, 20CrM04, 310, 316, 431, Al, Mhangura, nezvimwe.Midziyo yekuforoma ine 160tons, 300 tons, 400 tons, 630 tons, 1000 tons, 1600 tons, and 2500 tons, inogona kugadzira magiramu gumi kusvika ku55 kilograms yezvakakasharara zvekufogisa kana kunyatso forging zvigadzirwa.

Machining emidziyo ine lathe, muchina wekuchera, grinder, waya yekucheka, CNC uye zvichingodaro.

Kurapa kwekupisa kunosanganisira kujaira, kudziya, kuvhara, kudzima, mhinduro yakasimba, carburizing, nezvimwe.

Kurapa kwepamusoro kunosanganisira kuputika kwepfuti, kupuruzira pendi, electroplating, electrophoresis, phosphate uye zvichingodaro

Midziyo yekuyedza inosanganisira spectrometer, metallographic analyzer, kuoma mita, tensile muchina, kukanganisa kuyedza muchina, fluorescent magnetic particle flaw detector, ultrasonic flaw detector, matatu anoronga, nezvimwe.

Zvigadzirwa zvinoshandiswa zvakanyanya muindasitiri yepetrochemical, mainjiniya muchina, auto zvikamu, locomotive uye njanji zvikamu, metallurgy, shipbuilding, zvigadzirwa zvemauto nemimwe minda.

Mold development process

Chikwata cheR&D chinoitisa CAD dhizaini, CAM, UG, SOLIDWORKS basa rekuenzanisira.

Isu tinoshandisa superfine die steels seyakagadzirwa, tichibvumira kuti igadziriswe neCNC centre, tive nechokwadi chekuti simbi inofa inosimbiswa uye ine yakanakisa kuneta kuramba, abrasive kuramba, kuve nechokwadi chekuti mafogi anogadzirwa mumhando yepamusoro.

Kune anopfuura 2000 seti dze mold pano pakambani yedu.Vatengi vanogona kusarudza chero ipi zvayo yekugadzirisa kuderedza mutengo.Isu tinoita zvekutora, kujekesa uye kurekodha svondo rega rega kuti tive nechokwadi chekuti kugadzirwa kunofamba sezvakarongwa.

Yedu yekuchengetera mold inotungamirwa nekutevera iyo IATF16949 mhando manejimendi system uye "6S yakaonda manejimendi", ichipa hupenyu hwesevhisi kune mold uye ichiita kuti ive nyore kushandiswa nekuchengetedza.

Chikwata cheR&D chinoitisa CAD dhizaini, CAM, UG, SOLIDWORKS basa rekuenzanisira.

Isu tinoshandisa superfine die steels seyakagadzirwa, tichibvumira kuti igadziriswe neCNC centre, tive nechokwadi chekuti simbi inofa inosimbiswa uye ine yakanakisa kuneta kuramba, abrasive kuramba, kuve nechokwadi chekuti mafogi anogadzirwa mumhando yepamusoro.

Kune anopfuura 2000 seti dze mold pano pakambani yedu.Vatengi vanogona kusarudza chero ipi zvayo yekugadzirisa kuderedza mutengo.Isu tinoita zvekutora, kujekesa uye kurekodha svondo rega rega kuti tive nechokwadi chekuti kugadzirwa kunofamba sezvakarongwa.

Yedu yekuchengetera mold inotungamirwa nekutevera iyo IATF16949 mhando manejimendi system uye "6S yakaonda manejimendi", ichipa hupenyu hwesevhisi kune mold uye ichiita kuti ive nyore kushandiswa nekuchengetedza.

Kugadzira uye kugadzira

Isu tichagadzira uye kugadzira molds pakutambira kudhirowa kwemutengi kana masampuli, tobva tagadzira mold nekutevera dhizaini.Iyo mold inowanzo sanganisira forging dies, kudimburira kunofa.

Simbi billet kucheka uye kudziyisa

Kazhinji, isu tichagadzirira zvinhu zvinowanzo shandiswa mustock ine zvinhu nhamba ye20#, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q235, etc. choto chichashandiswa kudziyisa zvinhu zvakabikwa mune imwe tembiricha uye pakupedzisira kuisa tsvimbo yekudyira pasimbi yekugadzira.

Forging

Simbi isati yatanga, kumusoro nekuzasi kunofa kuchabatanidzwa kune anvil block yefoging press.Ipapo vashandi vanozotora zvinhu zvesimbi vozviisa pakati pemafaro ekugadzira kuti vawane chimiro chinodiwa nekutsikirira zvinhu zvesimbi kakawanda nepamusoro-kumhanya.

Kuchenesa

Mushure mekugadzira kwapera, pachave neasingadiwe maburrs akatenderedza akafukidzwa blanks, saka kubvisa maburrs inhanho inodiwa.Izvo zvinoda kuti vashandi vaise iyo yekuchekesa inofa pasi pechitsikiro chekutsikirira, vobva vadzvanya mazambuko akaumbwa kuti vachenese maburrs pamusoro pemafogi.

Kurapa kwekupisa

Kupisa kurapwa maitiro kunobatsira kuwana inodiwa mechanic kuita uye kuoma kwezvigadzirwa.The kupisa kurapa maitiro anofukidza normalizing, quenching, annealing, tempering, kuomesa uye zvichingodaro.

Shot blasting

Mushure mekupfurwa kwekuputika maitiro, mafogi achange aine nzvimbo yakatsetseka uye yakachena kupfuura zvayaizove.Kazhinji kutsetseka kwepamusoro kwefogi kunowanikwa muRa6.3, iyo inotonyanya kutsetseka kupfuura iyo yakarasika-wax casting.

Processing

Kune zvimwe zvikamu, maitiro ekugadzira haawanikwi mukushivirira kunodiwa, pasi penyaya iyi, kugadzirisa kunosarudzwa.Isu tichaitisa chigadzirwa kugadzirisa neakasiyana ekugadzira michina, kusanganisira muchina wekugaya, muchina unobhowa, muchina wekudhirowa, muchina wekukuya, nhamba yekudzora muchina nezvimwe.

Kurapa kwepamusoro

Muzviitiko zvakawanda, kana pasina chaidiwa zvinodiwa, tichava nemvura / mafuta ekudzivirira kudzivirira kurapwa pamusoro peiyo forgings.Tinogona zvakare kuitisa mamwe marapirwo epamusoro, anosanganisira kupfapfaidza pendi, poda coating, electroplating, electrocoating kusangana nezvinodiwa nevatengi vedu.

Kuongorora kwekupedzisira

Tichava nekuongorora pakukura kwechigadzirwa kuti tive nehupamhi hwepamusoro hwezvigadzirwa zvedu.Dzimwe nguva, tinewo mechanical performance uye makemikari emakemikari ekuongorora pane zvigadzirwa zvedu.

Package uye kutumira

Kazhinji, izvo zvakaumbwa zvinoiswa mumabhegi epolyethylene zvozoiswa mumabhokisi akasimba emapuranga.Isu tinokwanisa zvakare kugadzirisa mapakeji zvinoenderana nezvinodiwa nemutengi.Sezvo isu tiri muRuian forgings maindasitiri park, isu tine nyore kuwana kune zvigadzirwa zvekushandisa, izvo zvinodhura zvinobudirira pane zvese.

Isu tichagadzira uye kugadzira molds pakutambira kudhirowa kwemutengi kana masampuli, tobva tagadzira mold nekutevera dhizaini.Iyo mold inowanzo sanganisira forging dies, kudimburira kunofa.

Simbi billet kucheka uye kudziyisa

Kazhinji, isu tichagadzirira zvinhu zvinowanzo shandiswa mustock ine zvinhu nhamba ye20#, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q235, etc. choto chichashandiswa kudziyisa zvinhu zvakabikwa mune imwe tembiricha uye pakupedzisira kuisa tsvimbo yekudyira pasimbi yekugadzira.

Forging

Simbi isati yatanga, kumusoro nekuzasi kunofa kuchabatanidzwa kune anvil block yefoging press.Ipapo vashandi vanozotora zvinhu zvesimbi vozviisa pakati pemafaro ekugadzira kuti vawane chimiro chinodiwa nekutsikirira zvinhu zvesimbi kakawanda nepamusoro-kumhanya.

Kuchenesa

Mushure mekugadzira kwapera, pachave neasingadiwe maburrs akatenderedza akafukidzwa blanks, saka kubvisa maburrs inhanho inodiwa.Izvo zvinoda kuti vashandi vaise iyo yekuchekesa inofa pasi pechitsikiro chekutsikirira, vobva vadzvanya mazambuko akaumbwa kuti vachenese maburrs pamusoro pemafogi.

Kurapa kwekupisa

Kupisa kurapwa maitiro kunobatsira kuwana inodiwa mechanic kuita uye kuoma kwezvigadzirwa.The kupisa kurapa maitiro anofukidza normalizing, quenching, annealing, tempering, kuomesa uye zvichingodaro.

Shot blasting

Mushure mekupfurwa kwekuputika maitiro, mafogi achange aine nzvimbo yakatsetseka uye yakachena kupfuura zvayaizove.Kazhinji kutsetseka kwepamusoro kwefogi kunowanikwa muRa6.3, iyo inotonyanya kutsetseka kupfuura iyo yakarasika-wax casting.

Processing

Kune zvimwe zvikamu, maitiro ekugadzira haawanikwi mukushivirira kunodiwa, pasi penyaya iyi, kugadzirisa kunosarudzwa.Isu tichaitisa chigadzirwa kugadzirisa neakasiyana ekugadzira michina, kusanganisira muchina wekugaya, muchina unobhowa, muchina wekudhirowa, muchina wekukuya, nhamba yekudzora muchina nezvimwe.

Kurapa kwepamusoro

Muzviitiko zvakawanda, kana pasina chaidiwa zvinodiwa, tichava nemvura / mafuta ekudzivirira kudzivirira kurapwa pamusoro peiyo forgings.Tinogona zvakare kuitisa mamwe marapirwo epamusoro, anosanganisira kupfapfaidza pendi, poda coating, electroplating, electrocoating kusangana nezvinodiwa nevatengi vedu.

Kuongorora kwekupedzisira

Tichava nekuongorora pakukura kwechigadzirwa kuti tive nehupamhi hwepamusoro hwezvigadzirwa zvedu.Dzimwe nguva, tinewo mechanical performance uye makemikari emakemikari ekuongorora pane zvigadzirwa zvedu.

Package uye kutumira

Kazhinji, izvo zvakaumbwa zvinoiswa mumabhegi epolyethylene zvozoiswa mumabhokisi akasimba emapuranga.Isu tinokwanisa zvakare kugadzirisa mapakeji zvinoenderana nezvinodiwa nemutengi.Sezvo isu tiri muRuian forgings maindasitiri park, isu tine nyore kuwana kune zvigadzirwa zvekushandisa, izvo zvinodhura zvinobudirira pane zvese.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu