Tlhaloso

Sebopeho sa Sebopeho

● Lisebelisoa tse hatelitsoeng li sebelisa tšepe e phahameng ea alloy e nang le matla a matle le ho ba le tšusumetso e matla.

● Monyako oa monyako oa khatello e phahameng ea BOP o sebelisa tiiso e kopantsoeng, e nang le tiiso e molemo ho tloha khatellong ea seliba.

● Sebelisa heke e phaphametseng kapa e kenyellelitsoeng, e ka tiisang ka mokhoa o sireletsehileng le ho fetoha ha bonolo.

● Sebelisa tsela ea oli ea mofuta oa buriel, Hinge ea Bearing e arohane le hinge ea hydraulic.

● Sebopeho sa hinge se bonolo, se bonolo ho theola le ho se hloella.

● Sebelisa khetla e khōlō ea mofuta oa arc mahlakoreng ka bobeli a kamore, 'me u tsamaee ka mofuta oa arc ho pota-pota, ho fokotsa khatello ea tlhōrō ea khetla tlas'a khatello.

● Ka sebopeho se kopaneng, se senyane ho feta lihlahisoa tse tsoang kantle ho naha.

● Lekhapetla le ka hare la BOP le hanyetsanang le mocheso o tlase le khona ho sebetsana le liphaephe, ho etsa hore mouoane o phalle ka har'a BOP, o hlahisa mocheso.

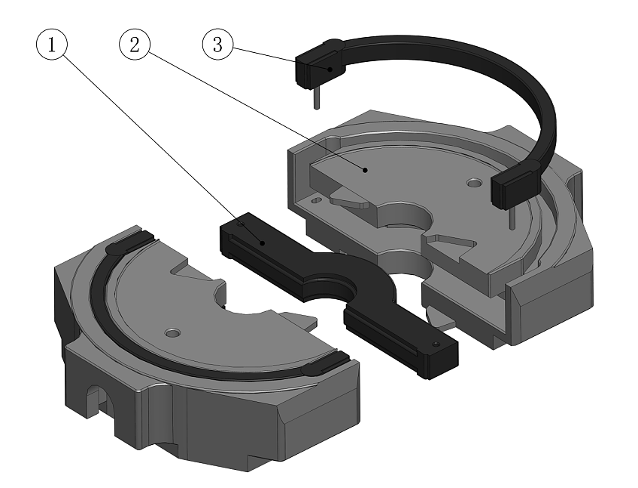

Kopano ea Ram

● Pipe Ram

| |

| 1. Top Tiiso 2. Ka pele Tiiso 3. 'Mele oa pheleu | 1. 'Mele oa pheleu 2. Bolt 3. Ram bolt 4. Ram rabara 5. Sets'oere |

| HF mofuta oa Ram o kopane | S mofuta oa Ram o kopane |

| | |

| |

| 1. 'Mele oa pheleu e ka tlaase 2. Rabara ea tiiso e ka holimo 3. Rabara ea tiiso e ka ho le letona 4. Top seal rabara 5. Left tiiso rabara 6. Up ho kuta pheleu 'mele | |

| Shear Ram Assembly Sebopeho sa S mofuta oa Ram BOP | |

Ram e feto-fetohang

Pheleu e feto-fetohang e ka sebelisoa ho tiisa bophara bo fapaneng ba khoele ea phala.Pheleu e feto-fetohang e entsoe ka pheleu e feto-fetohang, tiiso e holimo, tiiso e ka pele e fetohang.Ho kenngoa ha pheleu e feto-fetohang ho BOP ho tšoana le pheleu e tloaelehileng, ha ho hlokahale hore u fetole karolo efe kapa efe ea BOP.

| |||||||||

| Khatello ea ho sebetsa (psi) | Bore (ka) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | |||||||||

| 105-15000 | S | S | S | S | |||||

| 70-10000 | S | S | S | S | S | ||||

| 35-5000 | S | S | S | S | S | S | S | ||

| 21-3000 | S | S | S | S | S | S | S | ||

| 14-2000 | S | ||||||||

Tlhokomeliso: Tlhaloso le Mohlala oa S Ram BOP

S e emetse S mofuta oa pheleu BOP

| Tlhaloso &Mohlala | Main Bore mm(ka) | Khatello ea Mosebetsi MPa(psi) | Bongata ba oli bakeng sa ho buloa (Single Cylinder) | Bongata ba oli bakeng sa ho koala (Single Cylinder) | Mofuta oa Ram | Boholo ba Ram (ka hare) | Boemo mm | boima ba kg | Khoutu ea BOP e khothalelitsoeng | |||||

| bolelele | bophara | bophahamo | lesoha | habeli | ||||||||||

| lesoha | habeli | |||||||||||||

| 180(71/16 in) letoto | (2)FZ18-21 | 179.4(71/16) | 21-3000 | 1.6 | 2 | H | boholo5 9/16 | 1420 | 645 | 568 | 854 | 855 | 1540 | (2)S04.00 |

| (2)FZ18-35 | 179.4(71/16) | 35-5000 | 1.6 | 2 | H | boholo5 9/16 | 1420 | 645 | 624 | 910 | 895 | 1580 | (2)S48.00 | |

| (2)FZ18-70 | 179.4(71/16) | 70-10000 | 2.2 | 2.5 | H | boholo5 9/16 | 1720 | 640 | 897 | 1262 | 1660 | 3020 | (2)S62.00 | |

| (2)FZ18-105 | 179.4(71/16) | 105-15000 | 7.4 | 8 | H | boholo5 1/2 | 1988 | 820 | 922 | 1372 | 3175 | 5885 | (2)S29.00A | |

| 230(9in) letoto | (2)FZ23-21 | 228.6-9 | 21-3000 | 1.3 | 1.5 | HF | boholo 7 | 1526 | 565 | 580 | 866 | 705 | 1250 | (2)S79.00 |

| (2)FZ23-35 | 228.6-9 | 35-5000 | 4.7 | 5.3 | HF | boholo 7 | 2036 | 720 | 805 | 1190 | 1830 | 3415 | (2)S23.00 | |

| (2)FZ23-70 | 228.6-9 | 70-10000 | 7 | 8 | H | boholo 7 | 2324 | 850 | 1038 | 1518 | 3635 | 6835 | (2)S01.00 | |

| (2)FZ23-105 | 228.6-9 | 105-15000 | 10.2 | 10.9 | HF | boholo 7 | 2170 | 920 | 1140 | 1640 | 4150 | 7500 | (2)S93.00 | |

| 280(11in) letoto | (2)FZ28-21 | 279.4-11 | 21-3000 | 2.7 | 3.2 | S | boholo 8 5/8 | 1846 | 675 | 740 | 1100 | 1400 | 2550 | (2)S77.00 |

| (2)FZ28-35 | 279.4-11 | 35-5000 | 5.4 | 6.2 | S | boholo 8 5/8 | 2265 | 785 | 895 | 1325 | 2475 | 4550 | (2)S45.00 | |

| (2)FZ28-70 | 279.4-11 | 70-10000 | 7 | 8 | H | boholo 8 5/8 | 2324 | 850 | 1102 | 1582 | 3770 | 6850 | (2)S16.00 | |

| (2)FZ28-105 | 279.4-11 | 105-15000 | 14.6 | 16.7 | H | boholo 8 5/8 | 2650 | 1050 | 1244 | 1784 | 6303 | 11028 | (2)S67.00 | |

| 346(135/8 ho) letoto | (2)FZ35-21 | 346.1(135/8) | 21-3000 | 7.8 | 8.9 | S | boholo 10 3/4 | 2414 | 760 | 774 | 1164 | 2705 | 5115 | (2)S78.00 |

| (2)FZ35-35 | 346.1(135/8) | 35-5000 | 7.9 | 9.3 | S | boholo 10 3/4 | 2415 | 847 | 930 | 1370 | 3010 | 5480 | (2)S103.00 | |

| (2)FZ35-70 | 346.1(135/8) | 70-10000 | 18 | 20.7 | HF | boholo 10 3/4 | 2786 | 1085 | 1276 | 1782 | 6120 | 11135 | (2)S104.00 | |

| (2)FZ35-105 | 346.1(135/8) | 105-15000 | 17.4 | 20 | H | boholo 10 3/4 | 3074 | 1140 | 1420 | 1985 | 8945 | 16070 | (2)S115.00 | |

| 425(163/4 in) | (2)FZ43-35 | 425.5(163/4) | 35-5000 | 10.3 | 11.6 | HF | boholo 10 3/4 | 2923 | 1190 | 1090 | 1570 | 5300 | 9860 | (2)S95.00 |

| 476(183/4 ho) letoto | (2)FZ48-35 | 476.3(183/4) | 35-5000 | 24.5 | 27.9 | HF | boholo 16 | 3430 | 1440 | 1504 | 2072 | 9758 | 12286 | (2)S116.00 |

| (2)FZ48-70 | 476.3(183/4) | 70-10000 | 24.5 | 27.9 | HF | boholo 16 | 3430 | 1440 | 1618 | 2186 | 10312 | 20624 | (2)S102.00 | |

| 527(203/4in) | (2)FZ53-21 | 527.1(203/4) | 21-3000 | 12.2 | 13.6 | HF | boholo 16 | 3424 | 1165 | 1065 | 1650 | 6130 | 13355 | (2)S83.00 |

| 540(211/4 in) letoto | (2)FZ54-14 | 539.8(211/4) | 14-2000 | 12.1 | 13.8 | HF | boholo 16 | 3300 | 1130 | 940 | 1480 | 5560 | 10200 | (2)S33.00 |

| (2)FZ54-35 | 539.8(211/4) | 35-5000 | 26 | 29.6 | HF | boholo 16 | 3590 | 1445 | 1320 | 1950 | 9270 | 17670 | (2)S105.00 | |

| 680(263/4in) | (2)FZ68-21 | 679.5(263/4) | 21-3000 | 32.6 | 37 | HF | boholo 18 5/8 | 4350 | 1450 | 1250 | 1870 | 12360 | 20290 | (2)S87.00 |

| Tlhokomeliso:1.Khatello ea teko ea BOP ke linako tse 1.5 tsa khatello e tloaelehileng | ||||||||||||||

| 2. Khatello ea ts'ebetso e tsoa ho 8.4Mpa ho ea ho 10.5Mpa | ||||||||||||||

S Type Shear Ram Tlhaloso ea ts'ebetso

| Mofuta oa BOP | Mohlala oa BOP | Khoutu ea BOP e khothalelitsoeng | Mofuta oa Cylinder | Tlhaloso ea phala ea ho phunya |

| S | (2) FZ 18-70 | (2) S62.00 | Moqomo o tloaelehileng | |

| (2) S92.00 | Cylinder e nang le tandem booster | 4 1/2" 16.6lb/ft G-105 PSL-3 | ||

| (2) FZ28-35 | (2) S45.00 | Silinda e kholo | ||

| (2) S100.00 | Silinda e kholo | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 28-70 | (2) S16.00 | Moqomo o tloaelehileng | ||

| (2) S02.00 | Silinda e kholo | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-35 | (2) S103.00 | Moqomo o tloaelehileng | ||

| (2) S99.00 | Silinda e kholo | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-70 | (2) S104.00 | Moqomo o tloaelehileng | 5" 19.5lb/ft G-105 PSL-3 | |

| (2) S112.00 | Silinda e kholo | 5 1/2" 24.7lb/ft G-105 PSL-3 | ||

| (2) S117.00 | Cylinder e nang le tandem booster | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2) FZ 35-105 | (2) S115.00 | Moqomo o tloaelehileng | 5" 19.5lb/ft G-105 PSL-3 | |

| (2) S113.00 | Cylinder e nang le tandem booster | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2) FZ 54-35 | (2) S105.00 | Moqomo o tloaelehileng | 5" 19.5lb/ft G-105 PSL-3 |

S Mofuta o Fetohang oa Ram Range

| Mofuta oa BOP | Mohlala oa BOP | Range of Variable Ram (ka) | |||

| S | (2) FZ 18-70 | 2 3/8"-3 1/2" | |||

| (2) FZ28-35 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2) FZ 28-70 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2) FZ 35-35 | 2 3/8-3 1/2 | 2 7/8"-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-70 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-105 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 53-21 | 4 1/2"-5 1/2" | ||||

| (2) FZ 54-14 | 4 1/2"-5 1/2" | ||||

| (2) FZ 54-35 | 4 1/2"-5 1/2" | ||||

Thepa ea forging e na le lithane tse 160, lithane tse 300, lithane tse 400, lithane tse 630, lithane tse 1000, lithane tse 1600 le lithane tse 2500, li ka etsa ligrama tse leshome ho isa ho li-kilogramme tse 55 tsa lihlahisoa tse qhekellang kapa tse entsoeng ka nepo.

Lisebelisoa tsa machining li na le lathe, mochini oa ho phunya, grinder, terata, CNC joalo-joalo.

Kalafo ea mocheso e kenyelletsa ho tloaeleha, ho futhumatsa, ho koala, ho tima, tharollo e tiileng, carburizing, joalo-joalo.

Phekolo ea holim'a metsi e kenyelletsa ho phatloha ha sethunya, ho penta ho fafatsa, electroplating, electrophoresis, phosphate joalo-joalo

Lisebelisoa tsa tlhahlobo li kenyelletsa spectrometer, analyzer ea metallographic, meter ea thata, mochini o tsitsitseng, mochini oa tlhahlobo ea phello, sesebelisoa sa fluorescent magnetic particle flaw detector, ultrasonic flaw detector, likhokahano tse tharo, joalo-joalo.

Lihlahisoa li sebelisoa haholo indastering ea petrochemical, mechini ea boenjiniere, likarolo tsa likoloi, likarolo tsa literene le tsa terene, tšepe, kaho ea likepe, lihlahisoa tsa sesole le likarolo tse ling.

Sehlopha sa R&D se etsa moralo oa CAD, CAM, UG, SOLIDWORKS mosebetsi oa ho etsa mohlala.

Re sebelisa litšepe tsa superfine die e le thepa e tala, e li lumellang hore li sebetsanoe le setsi sa CNC, ho netefatsa hore ho nepahala ha tšepe ea die steel ho netefalitsoe ebile ho na le khanyetso e ntle ea mokhathala, ho hanyetsa abrasive, ho etsa bonnete ba hore forgings e hlahisoa ka boleng bo holimo.

Ho na le lihlopha tse fetang 2000 tsa hlobo mona k'hamphaning ea rona.Bareki ba ka khetha efe kapa efe ea bona bakeng sa ho e sebetsa ho fokotsa litšenyehelo.Re etsa lethathamo la lintho, ho hlakola le ho rekota beke e 'ngoe le e 'ngoe ho netefatsa hore tlhahiso e tsoela pele ka tsela e reriloeng.

Sebaka sa rona sa polokelo ea hlobo se laoloa ka ho latela tsamaiso ea boleng ba boleng ba IATF16949 le "6S lean management", ho fana ka bophelo bo bolelele ba tšebeletso ho hlobo le ho etsa hore e be bonolo bakeng sa tšebeliso le polokelo.

Re tla rala le ho etsa liforomo tsa forging ha re fumana litšoantšo kapa lisampole tsa moreki, ebe re etsa hlobo ka ho latela moralo oa hlobo.Hangata hlobo e kenyelletsa ho forging dies, trimming dies.

Steel billet seha le ho futhumatsa

Hangata, re tla lokisa thepa e sebelisoang khafetsa setokong se nang le thepa ea No. ea 20#, 35#, 45#, 20Cr, 40Cr, 20CrMnTi, 20CrMo, 30CrMo, 35CrMo, 42CrMo, Q235, joalo-joalo, A intermediate Q34 joalo-joalo. sebōpi se tla sebelisoa ho futhumatsa thepa e tala mochesong o itseng 'me qetellong ho behoe lere la ho jela holim'a moralo oa tšepe bakeng sa ho forging.

Ho qapa

Pele ts'ebetso ea ho forging ea tšepe e qala, karolo e ka holimo le e ka tlase e shoa e tla hokahanngoa le "anvil block" ea mochini oa khatiso oa forging.Joale basebetsi ba tla khetha lisebelisoa tsa tšepe ebe ba li beha pakeng tsa li-forging dies ho fihlela sebopeho se lakatsehang ka ho hatella lisebelisoa tsa tšepe ka makhetlo a 'maloa ka lebelo le phahameng.

Ho hloekisa

Ka mor'a hore forging e phethoe, ho tla ba le li-burrs tse sa batleheng ho pota-potile likheo tse entsoeng, kahoo ho tlosa li-burrs ke mohato o hlokahalang.E leng se hlokang hore basebetsi ba phahamise li-trimming ba shoela tlas'a mochine oa khatiso, ebe ba hatella likheo tse entsoeng ho hloekisa li-burrs holim'a li-forgings.

Phekolo ea mocheso

Ts'ebetso ea kalafo ea mocheso e thusa ho fumana ts'ebetso e hlokahalang ea mochini le boima ba lihlahisoa.Mekhoa ea phekolo ea mocheso e koahela normalizing, quenching, annealing, tempering, harding joalo-joalo.

Ho thunya

Ka mor'a ts'ebetso ea ho thunya, li-forging li tla ba le sebaka se boreleli le se hloekileng ho feta kamoo se neng se tla ba kateng.Hangata boreleli ba holim'a li-forging bo fumaneha ho Ra6.3, e leng e bonolo le ho feta ea ho lahleheloa ke boka ba boka.

Ho sebetsa

Bakeng sa likarolo tse ling, mokhoa oa ho qhekella ha o fumanehe ka mamello e hlokahalang, tlas'a taba ena, ts'ebetso ke khetho.Re tla tsamaisa ts'ebetso ea sehlahisoa ka lisebelisoa tse fapaneng tsa ts'ebetso, ho kenyeletsoa mochini oa ho sila, mochini o borehang, mochini oa ho phunya, mochini o silang, mochini o laolang linomoro jj.

Phekolo ea bokaholimo

Maemong a mangata, haeba ho se na litlhoko tse khethehileng tse hlokahalang, re tla ba le kalafo ea ts'ireletso ea mafome a metsi / oli holim'a liforomo.Re ka boela ra etsa liphekolo tse ling ka holim'a metsi, ho kenyelletsa ho fafatsa ka pente, ho roala phofo, ho roala ka motlakase, ho etsa motlakase ho fihlela litlhoko tse khethehileng tsa bareki ba rona.

Tlhahlobo ea ho qetela

Re tla ba le tlhahlobo ea boholo ba sehlahisoa ho netefatsa boleng bo phahameng ba lihlahisoa tsa rona.Ka linako tse ling, re boetse re na le ts'ebetso ea mechine le tlhahlobo ea likarolo tsa lik'hemik'hale lihlahisoa tsa rona.

Sephutheloana le thomello

Maemong a mangata, likarolo tse entsoeng li tla kenngoa ka mekotleng ea polyethylene ebe li kenngoa ka har'a mabokose a tiileng a lehong.Re boetse re khona ho iketsetsa liphutheloana ho latela litlhoko tsa moreki.Ha re ntse re le serapeng sa boikhathollo sa Ruian forgings, re na le phihlello e bonolo ea phepelo ea thepa e tala, e theko e boima ka kakaretso.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu