Katerangan

Fitur Struktural

● komponén Pressurized adopts baja alloy punjul kalawan kakuatan alus tur kateguhan dampak.

● Door segel tina BOP tekanan tinggi migunakeun segel digabungkeun, nu boga segel hadé ti tekanan sumur.

● Paké floating atanapi Gerbang integral, bisa ngégél aman tur ngarobah merenah.

● Paké buriel-tipe petikan minyak, Bearing hinge dipisahkeun tina hinge hidrolik.

● struktur hinge téh basajan, gampang dismount na Gunung.

● Paké badag arc-tipe cangkang dina dua sisi chamber, sarta transit ku arc-tipe sadayana sabudeureun, pikeun ngurangan stress puncak cangkang dina tekenan.

● Kalawan struktur kompak, leuwih leutik batan produk asing sarupa.

● cangkang internal BOP tahan ka hawa low bisa ngolah pipa, sangkan aliran uap jero BOP, radiat panas.

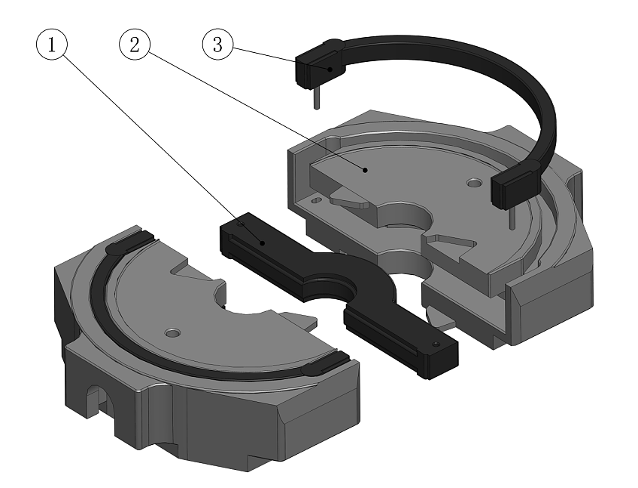

Majelis Ram

● Ram Pipa

| |

| 1. segel luhur 2. segel hareup 3. awak Ram | 1. Awak Ram 2. Bolt 3. Ram baud 4. Ram karét 5. Panyekel clamp |

| HF tipe Ram ngumpul | S tipe Ram ngumpul |

| | |

| |

| 1. Handapeun shear ram body 2. Top seal rubber 3. Katuhu seal rubber 4. Blade sealLeft seal rubber 3. Up shear ram body 4. Top segel karét 5. Kenca segel karét 6. Nepi geser ram awak | |

| Geser Ram Struktur Majelis S tipe Ram BOP | |

Variabel Ram

ram variabel bisa dipaké pikeun ngégél diaméter béda tina senar pipe.Variable ram diwangun ku variabel ram, segel luhur, segel hareup variabel.Pamasangan ram variabel dina BOP sami sareng ram biasa, henteu kedah ngarobih bagian mana waé BOP.

| |||||||||

| Tekanan operasi (psi) | Bore (di) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | |||||||||

| 105-15000 | S | S | S | S | |||||

| 70-10000 | S | S | S | S | S | ||||

| 35-5000 | S | S | S | S | S | S | S | ||

| 21-3000 | S | S | S | S | S | S | S | ||

| 14-2000 | S | ||||||||

Catetan: S Ram BOP Spésifikasi & Modél

S ngagambarkeun S tipe ram BOP

| Spésifikasi & Modél | Lubang Utama mm (dina) | Tekanan Gawé MPa (psi) | Jumlah minyak pikeun bubuka (Silinder Tunggal) | Kuantitas minyak pikeun nutup (Silinder Tunggal) | Jenis Ram | Ukuran Ram (di) | Diménsi mm | beurat kg | Disarankeun kode BOP | |||||

| panjangna | lebar | jangkungna | tunggal | ganda | ||||||||||

| tunggal | ganda | |||||||||||||

| 180 (71/16 di) runtuyan | (2) FZ18-21 | 179.4(71/16) | 21-3000 | 1.6 | 2 | H | maksimum5 9/16 | 1420 | 645 | 568 | 854 | 855 | 1540 | (2)S04.00 |

| (2) FZ18-35 | 179.4(71/16) | 35-5000 | 1.6 | 2 | H | maksimum5 9/16 | 1420 | 645 | 624 | 910 | 895 | 1580 | (2)S48.00 | |

| (2) FZ18-70 | 179.4(71/16) | 70-10000 | 2.2 | 2.5 | H | maksimum5 9/16 | 1720 | 640 | 897 | 1262 | 1660 | 3020 | (2)S62.00 | |

| (2) FZ18-105 | 179.4(71/16) | 105-15000 | 7.4 | 8 | H | maksimum5 1/2 | 1988 | 820 | 922 | 1372 | 3175 | 5885 | (2)S29.00A | |

| 230 (9in) runtuyan | (2) FZ23-21 | 228.6-9 | 21-3000 | 1.3 | 1.5 | HF | maksimal 7 | 1526 | 565 | 580 | 866 | 705 | 1250 | (2)S79.00 |

| (2) FZ23-35 | 228.6-9 | 35-5000 | 4.7 | 5.3 | HF | maksimal 7 | 2036 | 720 | 805 | 1190 | 1830 | 3415 | (2)S23.00 | |

| (2) FZ23-70 | 228.6-9 | 70-10000 | 7 | 8 | H | maksimal 7 | 2324 | 850 | 1038 | 1518 | 3635 | 6835 | (2)S01.00 | |

| (2) FZ23-105 | 228.6-9 | 105-15000 | 10.2 | 10.9 | HF | maksimal 7 | 2170 | 920 | 1140 | 1640 | 4150 | 7500 | (2)S93.00 | |

| 280 (11in) runtuyan | (2) FZ28-21 | 279.4-11 | 21-3000 | 2.7 | 3.2 | S | maksimum 8 5/8 | 1846 | 675 | 740 | 1100 | 1400 | 2550 | (2)S77.00 |

| (2) FZ28-35 | 279.4-11 | 35-5000 | 5.4 | 6.2 | S | maksimum 8 5/8 | 2265 | 785 | 895 | 1325 | 2475 | 4550 | (2)S45.00 | |

| (2) FZ28-70 | 279.4-11 | 70-10000 | 7 | 8 | H | maksimum 8 5/8 | 2324 | 850 | 1102 | 1582 | 3770 | 6850 | (2)S16.00 | |

| (2) FZ28-105 | 279.4-11 | 105-15000 | 14.6 | 16.7 | H | maksimum 8 5/8 | 2650 | 1050 | 1244 | 1784 | 6303 | 11028 | (2)S67.00 | |

| 346 (135/8 di) runtuyan | (2) FZ35-21 | 346.1(135/8) | 21-3000 | 7.8 | 8.9 | S | maksimum 10 3/4 | 2414 | 760 | 774 | 1164 | 2705 | 5115 | (2)S78.00 |

| (2) FZ35-35 | 346.1(135/8) | 35-5000 | 7.9 | 9.3 | S | maksimum 10 3/4 | 2415 | 847 | 930 | 1370 | 3010 | 5480 | (2)S103.00 | |

| (2) FZ35-70 | 346.1(135/8) | 70-10000 | 18 | 20.7 | HF | maksimum 10 3/4 | 2786 | 1085 | 1276 | 1782 | 6120 | 11135 | (2)S104.00 | |

| (2) FZ35-105 | 346.1(135/8) | 105-15000 | 17.4 | 20 | H | maksimum 10 3/4 | 3074 | 1140 | 1420 | 1985 | 8945 | 16070 | (2)S115.00 | |

| 425 (163/4 inci) | (2) FZ43-35 | 425.5(163/4) | 35-5000 | 10.3 | 11.6 | HF | maksimum 10 3/4 | 2923 | 1190 | 1090 | 1570 | 5300 | 9860 | (2)S95.00 |

| 476 (183/4 di) runtuyan | (2) FZ48-35 | 476.3(183/4) | 35-5000 | 24.5 | 27.9 | HF | maksimal 16 | 3430 | 1440 | 1504 | 2072 | 9758 | 12286 | (2)S116.00 |

| (2) FZ48-70 | 476.3(183/4) | 70-10000 | 24.5 | 27.9 | HF | maksimal 16 | 3430 | 1440 | 1618 | 2186 | 10312 | 20624 | (2)S102.00 | |

| 527(203/4in) | (2) FZ53-21 | 527.1(203/4) | 21-3000 | 12.2 | 13.6 | HF | maksimal 16 | 3424 | 1165 | 1065 | 1650 | 6130 | 13355 | (2)S83.00 |

| 540 (211/4 di) runtuyan | (2) FZ54-14 | 539.8(211/4) | 14-2000 | 12.1 | 13.8 | HF | maksimal 16 | 3300 | 1130 | 940 | 1480 | 5560 | 10200 | (2)S33.00 |

| (2) FZ54-35 | 539.8(211/4) | 35-5000 | 26 | 29.6 | HF | maksimal 16 | 3590 | 1445 | 1320 | 1950 | 9270 | 17670 | (2)S105.00 | |

| 680(263/4in) | (2) FZ68-21 | 679.5(263/4) | 21-3000 | 32.6 | 37 | HF | maksimum 18 5/8 | 4350 | 1450 | 1250 | 1870 | 12360 | 20290 | (2)S87.00 |

| Catetan: 1.Tekanan Uji BOP nyaéta 1,5 kali tekanan standar | ||||||||||||||

| 2. tekanan operasi nyaeta ti 8.4Mpa mun 10.5Mpa | ||||||||||||||

S Tipe Shear Ram spésifikasi Operasi

| Tipe BOP | modél BOP | Disarankeun kode BOP | Tipe Silinder | Spésifikasi pipa bor |

| S | (2) FZ 18-70 | (2)S62.00 | Silinder normal | |

| (2)S92.00 | Silinder kalawan tandem booster | 4 1/2" 16,6lb/ft G-105 PSL-3 | ||

| (2) FZ28-35 | (2)S45.00 | silinder badag | ||

| (2)S100,00 | silinder badag | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 28-70 | (2)S16.00 | Silinder normal | ||

| (2)S02.00 | silinder badag | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-35 | (2)S103.00 | Silinder normal | ||

| (2)S99.00 | silinder badag | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-70 | (2)S104.00 | Silinder normal | 5" 19.5lb/ft G-105 PSL-3 | |

| (2)S112.00 | silinder badag | 5 1/2" 24,7lb/ft G-105 PSL-3 | ||

| (2)S117.00 | Silinder kalawan tandem booster | 5 1/2" 24,7lb/ft S-135 PSL-3 | ||

| (2) FZ 35-105 | (2)S115.00 | Silinder normal | 5" 19.5lb/ft G-105 PSL-3 | |

| (2)S113.00 | Silinder kalawan tandem booster | 5 1/2" 24,7lb/ft S-135 PSL-3 | ||

| (2) FZ 54-35 | (2)S105.00 | Silinder normal | 5" 19.5lb/ft G-105 PSL-3 |

S Tipe Variable Ram Range

| Tipe BOP | Modél BOP | Kisaran Variabel Ram (dina) | |||

| S | (2) FZ 18-70 | 2 3/8" - 3 1/2" | |||

| (2) FZ28-35 | 2 3/8" - 3 1/2" | 3 1/2"-5" | |||

| (2) FZ 28-70 | 2 3/8" - 3 1/2" | 3 1/2"-5" | |||

| (2) FZ 35-35 | 2 3/8-3 1/2 | 2 7/8"-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-70 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-105 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 53-21 | 4 1/2" - 5 1/2" | ||||

| (2) FZ 54-14 | 4 1/2" - 5 1/2" | ||||

| (2) FZ 54-35 | 4 1/2" - 5 1/2" | ||||

Parabot Forging boga 160ton, 300 ton, 400 ton, 630 ton, 1000 ton, 1600 ton, jeung 2500 ton, bisa forge sapuluh gram nepi ka 55 kilogram forging kasar atawa precision forging produk.

alat-alat Machining boga lathe, mesin pangeboran, coét, motong kawat, CNC jeung saterusna.

perlakuan panas ngawengku normalizing, tempering, annealing, quenching, solusi padet, carburizing, jsb

Perlakuan permukaan ngawengku shot blasting, lukisan semprot, electroplating, Éléktroforésis, fosfat jeung saterusna

Alat-alat tés kalebet spéktrométer, analisa metalografi, méter karasa, mesin tensile, mesin uji dampak, detektor cacad partikel magnét fluoresensi, detektor cacad ultrasonik, tilu koordinat, jsb.

Produk anu loba dipaké dina industri pétrokimia, mesin rékayasa, suku cadang mobil, lokomotif jeung bagian kareta api, metallurgy, shipbuilding, produk militér jeung widang lianna.

Tim R&D ngalaksanakeun desain CAD, CAM, UG, SOLIDWORKS karya modeling.

Kami nganggo baja paeh superfine salaku bahan baku, ngamungkinkeun aranjeunna diolah ku pusat CNC, mastikeun katepatan baja paeh dipastikeun sareng gaduh résistansi kacapean anu saé, résistansi abrasive, mastikeun yén tempaan diproduksi dina kualitas luhur.

Aya leuwih ti 2000 sét molds didieu di parusahaan urang.Konsumén tiasa milih salah sahiji pikeun diolah pikeun ngaminimalkeun biaya.Urang ngalakukeun inventory nyokot, clearing jeung ngarékam unggal minggu pikeun mastikeun yén produksi proceeds sakumaha dijadwalkeun.

Gudang kapang kami dikokolakeun ku nuturkeun sistem manajemen kualitas IATF16949 sareng "manajemén lean 6S", masihan umur jasa anu panjang pikeun kapang sareng ngajantenkeun pikeun dianggo sareng neundeun.

Urang bakal ngarancang jeung rancang forging molds on resi gambar customer urang atawa sampel, lajeng urang bakal rancang kapang ku nuturkeun desain kapang.The molds mindeng kaasup forging paeh, trimming maot.

Pamotongan billet baja sareng pemanasan

Seringna, urang bakal nyiapkeun bahan anu sering dianggo dina saham anu nampilkeun bahan No. tungku bakal dipaké pikeun pemanasan bahan baku kana suhu nu tangtu sarta tungtungna nempatkeun rod dahar dina kerangka logam pikeun forging.

Ngajalin

Sateuacan prosés ngajalin logam dimimitian, bagian luhur sareng handap maot kedah dihubungkeun sareng blok anvil pikeun pencét pencét.Lajeng pagawe bakal nyokot bahan logam jeung nempatkeun aranjeunna diantara forging paeh pikeun ngahontal bentuk dipikahoyong ku mencét bahan logam sababaraha kali kalayan speed tinggi.

beberesih

Saatos forging réngsé, bakal aya burrs nu teu dihoyongkeun sabudeureun blanks ngajalin, jadi nyoplokkeun burrs mangrupakeun hambalan diperlukeun.Anu meryogikeun pagawé pikeun masang trimming di handapeun pencét punching, teras mencét kosong palsu pikeun ngabersihan burrs dina permukaan tempa.

perlakuan panas

Prosés perlakuan panas mantuan pikeun meunangkeun kinerja mékanis diperlukeun tur karasa produk.Téhnik perlakuan panas nutupan normalizing, quenching, annealing, tempering, hardening jeung saterusna.

Ditémbak blasting

Saatos prosés shot blasting, anu forgings bakal boga permukaan smoother tur cleaner ti eta bakal geus.Biasana smoothness permukaan forgings sadia dina Ra6.3, nu malah smoother ti casting leungit-lilin.

Ngolah

Pikeun sababaraha komponén, prosés forging henteu sayogi dina kasabaran anu diperyogikeun, dina hal ieu, pamrosésan nyaéta pilihan.Kami bakal ngalaksanakeun pamrosésan produk sareng alat pangolahan anu béda, kalebet mesin panggilingan, mesin boring, pencét bor, mesin grinding, mesin kontrol numerik jsb.

Perlakuan permukaan

Dina kalolobaan kasus, lamun euweuh sarat husus diperlukeun, urang bakal boga perlakuan panyalindungan karat cai / minyak dina beungeut forgings.Urang ogé bisa ngalaksanakeun perlakuan permukaan lianna, kaasup cet nyemprot, powder coating, electroplating, electrocoating pikeun minuhan kabutuhan husus konsumén urang.

ujian ahir

Urang bakal boga inspeksi dina ukuran produk pikeun mastikeun kualitas luhur products.Sometimes urang, urang ogé boga kinerja mékanis jeung komponén kimiawi nguji dina produk urang.

Paket sareng pangiriman

Dina kalolobaan kasus, komponén ngajalin bakal ngarangkep dina kantong poliétilén teras disimpen kana kotak kayu teguh.Kami ogé tiasa ngarobih bungkusan dumasar kana kabutuhan palanggan.Salaku urang lokasina di Ruian forgings taman industri, urang boga aksés gampang kana suplai bahan baku, nu ongkos éféktif dina sakabéh.