Incazelo

Isici Sesakhiwo

● Izingxenye ezicindezelwe zisebenzisa insimbi ye-alloy ephakeme kakhulu enamandla amahle kanye nokuqina okunomthelela.

● Isivalo somnyango se-BOP yengcindezi ephezulu sisebenzisa uphawu oluhlanganisiwe, olunophawu olungcono olusuka kungcindezi yomthombo.

● Sebenzisa isango elintantayo noma elihlanganisiwe, lingavaleka ngokuphephile futhi lishintshe kalula.

● Sebenzisa uwoyela wohlobo lwe-buriel, i-Bearing hinge ihlukaniswe nehinji ye-hydraulic.

● Isakhiwo sehinge silula, kulula ukwehliswa nokusikhweza.

● Sebenzisa igobolondo elikhulu lohlobo lwe-arc kuzo zombili izinhlangothi zegumbi, futhi uhambe ngohlobo lwe-arc nxazonke, ukuze unciphise ukucindezelwa okuphezulu kwegobolondo ngaphansi kwengcindezi.

● Ngesakhiwo esihlangene, esincane kunemikhiqizo yangaphandle efanayo.

● Igobolondo langaphakathi le-BOP limelana nezinga lokushisa eliphansi lingacubungula ipayipi, ukwenza isitimu sigeleze ngaphakathi kwe-BOP, sikhiphe ukushisa.

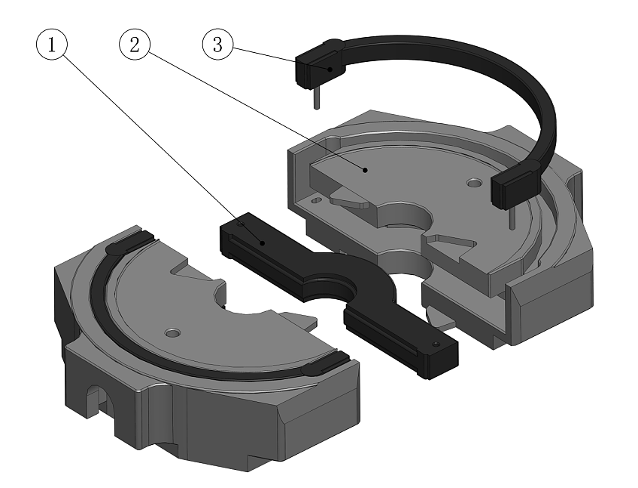

I-Ram Assembly

● I-Pipe Ram

| |

| 1. Uphawu oluphezulu 2. Uphawu lwangaphambili 3. Umzimba wenqama | 1. Umzimba wenqama 2. Ibhawodi 3. Ibhawodi lenqama 4. Irabha yenqama 5. Isibambi sokubambelela |

| I-HF uhlobo lwe-Ram assembl | S thayipha i-Ram assembl |

| | |

| |

| 1. Umzimba wenqama egundayo 2. Irabha ecijile phezulu 3. Irabha yophawu lwesokudla 4. I-blade sealIrabha yophawu lwesobunxele 3. Umzimba wenqama yokugunda phezulu 4. Irabha yophawu oluphezulu 5. Irabha yophawu lwesokunxele 6. Umzimba wenqama yokugunda phezulu | |

| Isakhiwo somhlangano we-Shear Ram sohlobo lwe-S lwe-Ram BOP | |

I-Ram eguquguqukayo

Inqama eguquguqukayo ingasetshenziswa ukuvala ububanzi obuhlukene bentambo yepayipi.Inqama eguquguqukayo yakhiwe ngenqama eguquguqukayo, uphawu oluphezulu, uphawu lwangaphambili oluguquguqukayo.Ukufakwa kwenqama eguquguqukayo ku-BOP kufana nenqama evamile, akudingekile ukushintsha noma iyiphi ingxenye ye-BOP.

| |||||||||

| Ingcindezi yokusebenza (psi) | Bore (in) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | |||||||||

| 105-15000 | S | S | S | S | |||||

| 70-10000 | S | S | S | S | S | ||||

| 35-5000 | S | S | S | S | S | S | S | ||

| 21-3000 | S | S | S | S | S | S | S | ||

| 14-2000 | S | ||||||||

Qaphela: Ukucaciswa kwe-S Ram BOP & Imodeli

U-S umele uhlobo luka-S lwenqama ye-BOP

| Ukucaciswa & Imodeli | I-Main Bore mm(in) | Ingcindezi Yokusebenza I-MPa(psi) | Ubuningi bamafutha okuvulwa (Isilinda Single) | Inani likawoyela lokuvala (Single Cylinder) | Uhlobo Lwenqama | Usayizi weRam (ngaphakathi) | Ubukhulu mm | isisindo kg | Ikhodi ye-BOP enconyiwe | |||||

| ubude | ububanzi | ukuphakama | ongashadile | kabili | ||||||||||

| ongashadile | kabili | |||||||||||||

| 180(71/16 in)uchungechunge | (2)FZ18-21 | 179.4(71/16) | 21-3000 | 1.6 | 2 | H | ubuningi 5 9/16 | 1420 | 645 | 568 | 854 | 855 | 1540 | (2)S04.00 |

| (2)FZ18-35 | 179.4(71/16) | 35-5000 | 1.6 | 2 | H | ubuningi 5 9/16 | 1420 | 645 | 624 | 910 | 895 | 1580 | (2)S48.00 | |

| (2)FZ18-70 | 179.4(71/16) | 70-10000 | 2.2 | 2.5 | H | ubuningi 5 9/16 | 1720 | 640 | 897 | 1262 | 1660 | 3020 | (2)S62.00 | |

| (2)FZ18-105 | 179.4(71/16) | 105-15000 | 7.4 | 8 | H | ubuningi 5 1/2 | 1988 | 820 | 922 | 1372 | 3175 | 5885 | (2)S29.00A | |

| 230(9in)uchungechunge | (2)FZ23-21 | 228.6-9 | 21-3000 | 1.3 | 1.5 | HF | esiphezulu 7 | 1526 | 565 | 580 | 866 | 705 | 1250 | (2)S79.00 |

| (2)FZ23-35 | 228.6-9 | 35-5000 | 4.7 | 5.3 | HF | esiphezulu 7 | 2036 | 720 | 805 | 1190 | 1830 | 3415 | (2)S23.00 | |

| (2)FZ23-70 | 228.6-9 | 70-10000 | 7 | 8 | H | esiphezulu 7 | 2324 | 850 | 1038 | 1518 | 3635 | 6835 | (2)S01.00 | |

| (2)FZ23-105 | 228.6-9 | 105-15000 | 10.2 | 10.9 | HF | esiphezulu 7 | 2170 | 920 | 1140 | 1640 | 4150 | 7500 | (2)S93.00 | |

| 280(11in)uchungechunge | (2)FZ28-21 | 279.4-11 | 21-3000 | 2.7 | 3.2 | S | ubuningi 8 5/8 | 1846 | 675 | 740 | 1100 | 1400 | 2550 | (2)S77.00 |

| (2)FZ28-35 | 279.4-11 | 35-5000 | 5.4 | 6.2 | S | ubuningi 8 5/8 | 2265 | 785 | 895 | 1325 | 2475 | 4550 | (2)S45.00 | |

| (2)FZ28-70 | 279.4-11 | 70-10000 | 7 | 8 | H | ubuningi 8 5/8 | 2324 | 850 | 1102 | 1582 | 3770 | 6850 | (2)S16.00 | |

| (2)FZ28-105 | 279.4-11 | 105-15000 | 14.6 | 16.7 | H | ubuningi 8 5/8 | 2650 | 1050 | 1244 | 1784 | 6303 | 11028 | (2)S67.00 | |

| 346(135/8 in)uchungechunge | (2)FZ35-21 | 346.1(135/8) | 21-3000 | 7.8 | 8.9 | S | ubuningi 10 3/4 | 2414 | 760 | 774 | 1164 | 2705 | 5115 | (2)S78.00 |

| (2)FZ35-35 | 346.1(135/8) | 35-5000 | 7.9 | 9.3 | S | ubuningi 10 3/4 | 2415 | 847 | 930 | 1370 | 3010 | 5480 | (2)S103.00 | |

| (2)FZ35-70 | 346.1(135/8) | 70-10000 | 18 | 20.7 | HF | ubuningi 10 3/4 | 2786 | 1085 | 1276 | 1782 | 6120 | 11135 | (2)S104.00 | |

| (2)FZ35-105 | 346.1(135/8) | 105-15000 | 17.4 | 20 | H | ubuningi 10 3/4 | 3074 | 1140 | 1420 | 1985 | 8945 | 16070 | (2)S115.00 | |

| 425(163/4 in) | (2)FZ43-35 | 425.5(163/4) | 35-5000 | 10.3 | 11.6 | HF | ubuningi 10 3/4 | 2923 | 1190 | 1090 | 1570 | 5300 | 9860 | (2)S95.00 |

| 476(183/4 in)uchungechunge | (2)FZ48-35 | 476.3(183/4) | 35-5000 | 24.5 | 27.9 | HF | esiphezulu 16 | 3430 | 1440 | 1504 | 2072 | 9758 | 12286 | (2)S116.00 |

| (2)FZ48-70 | 476.3(183/4) | 70-10000 | 24.5 | 27.9 | HF | esiphezulu 16 | 3430 | 1440 | 1618 | 2186 | 10312 | 20624 | (2)S102.00 | |

| 527(203/4in) | (2)FZ53-21 | 527.1(203/4) | 21-3000 | 12.2 | 13.6 | HF | esiphezulu 16 | 3424 | 1165 | 1065 | 1650 | 6130 | 13355 | (2)S83.00 |

| 540(211/4 in)uchungechunge | (2)FZ54-14 | 539.8(211/4) | 14-2000 | 12.1 | 13.8 | HF | esiphezulu 16 | 3300 | 1130 | 940 | 1480 | 5560 | 10200 | (2)S33.00 |

| (2)FZ54-35 | 539.8(211/4) | 35-5000 | 26 | 29.6 | HF | esiphezulu 16 | 3590 | 1445 | 1320 | 1950 | 9270 | 17670 | (2)S105.00 | |

| 680(263/4in) | (2)FZ68-21 | 679.5(263/4) | 21-3000 | 32.6 | 37 | HF | ubuningi 18 5/8 | 4350 | 1450 | 1250 | 1870 | 12360 | 20290 | (2)S87.00 |

| Qaphela:1.Ingcindezi yokuhlola ye-BOP izikhathi ezingu-1.5 zokucindezela okujwayelekile | ||||||||||||||

| 2. Ingcindezi yokusebenza isuka ku-8.4Mpa iye ku-10.5Mpa | ||||||||||||||

Ukucaciswa kokusebenza kwe-Shear Ram ye-S

| Uhlobo lwe-BOP | Imodeli ye-BOP | Ikhodi ye-BOP enconyiwe | Uhlobo Lwesilinda | Ukucaciswa kwepayipi lokubhoboza |

| S | (2) FZ 18-70 | (2) S62.00 | Isilinda esivamile | |

| (2) S92.00 | Isilinda esine-tandem booster | 4 1/2" 16.6lb/ft G-105 PSL-3 | ||

| (2) FZ28-35 | (2) S45.00 | Isilinda esikhulu | ||

| (2) S100.00 | Isilinda esikhulu | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 28-70 | (2) S16.00 | Isilinda esivamile | ||

| (2) S02.00 | Isilinda esikhulu | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-35 | (2) S103.00 | Isilinda esivamile | ||

| (2) S99.00 | Isilinda esikhulu | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2) FZ 35-70 | (2) S104.00 | Isilinda esivamile | 5" 19.5lb/ft G-105 PSL-3 | |

| (2) S112.00 | Isilinda esikhulu | 5 1/2" 24.7lb/ft G-105 PSL-3 | ||

| (2) S117.00 | Isilinda esine-tandem booster | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2) FZ 35-105 | (2) S115.00 | Isilinda esivamile | 5" 19.5lb/ft G-105 PSL-3 | |

| (2) S113.00 | Isilinda esine-tandem booster | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2) FZ 54-35 | (2) S105.00 | Isilinda esivamile | 5" 19.5lb/ft G-105 PSL-3 |

Uhlobo lwe-S oluguquguqukayo lweRam Range

| Uhlobo lwe-BOP | Imodeli ye-BOP | Ububanzi beRam eguquguqukayo (in) | |||

| S | (2) FZ 18-70 | 2 3/8"-3 1/2" | |||

| (2) FZ28-35 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2) FZ 28-70 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2) FZ 35-35 | 2 3/8-3 1/2 | 2 7/8"-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-70 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 35-105 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2) FZ 53-21 | 4 1/2"-5 1/2" | ||||

| (2) FZ 54-14 | 4 1/2"-5 1/2" | ||||

| (2) FZ 54-35 | 4 1/2"-5 1/2" | ||||

Imishini yokubumba inamathani ayi-160, amathani angama-300, amathani angama-400, amathani angama-630, amathani ayi-1000, amathani ayi-1600 kanye namathani angama-2500, ingakha amagremu ayishumi kuye kumakhilogremu angama-55 wemikhiqizo yokubumba eqinile noma eqondile.

Imishini yomshini ine-lathe, umshini wokubhoboza, umshini wokugaya, ukusika izintambo, i-CNC nokunye.

Ukwelashwa kokushisa kuhlanganisa ukujwayelekile, ukuthulisa, ukuthulisa, ukucisha, isixazululo esiqinile, ukungcwatshwa kwe-carburizing, njll.

Ukwelashwa okungaphezulu kuhlanganisa ukuqhunyiswa kwesibhamu, ukupenda kwesifutho, i-electroplating, i-electrophoresis, i-phosphate nokunye

Imishini yokuhlola ihlanganisa i-spectrometer, i-metallographic analyzer, imitha yobulukhuni, umshini oqinile, umshini wokuhlola umthelela, umtshina we-fluorescent magnetic flaw flaw, umtshina we-ultrasonic flaw, izixhumanisi ezintathu, njll.

Imikhiqizo isetshenziswa kabanzi embonini ye-petrochemical, imishini yobunjiniyela, izingxenye zezimoto, izingxenye zesitimela nesitimela, i-metallurgy, ukwakhiwa kwemikhumbi, imikhiqizo yezempi neminye imikhakha.

Ithimba le-R&D lenza ukuklama kwe-CAD, i-CAM, i-UG, umsebenzi wokumodela we-SOLIDWORKS.

Sisebenzisa ama-superfine die steels njengezinto ezingavuthiwe, ezivumela ukuthi zicutshungulwe ngesikhungo se-CNC, siqinisekisa ukuthi ukunemba kwe-die steel kuyaqinisekiswa futhi inokumelana nokukhathala okuhle kakhulu, ukumelana nokuthuthumela, siqinisekisa ukuthi ama-forging akhiqizwa ngekhwalithi ephezulu.

Kukhona amasethi angaphezu kuka-2000 esikhunta lapha enkampanini yethu.Amakhasimende angakhetha noma iyiphi yazo ukuze icutshungulwe ukuze kuncishiswe izindleko.Senza ukuthatha i-inventory, ukususa nokuqopha masonto onke ukuze siqinisekise ukuthi ukukhiqiza kuqhubeka njengoba kuhleliwe.

Indawo yethu yokugcina isikhunta ilawulwa ngokulandela isistimu yokuphatha ikhwalithi ye-IATF16949 kanye “nokuphathwa kwe-6S ethambile”, enikeza impilo ende yesevisi kusikhunta nokwenza kube lula ukusetshenziswa nokugcinwa.

Sizoklama futhi sikhiqize isikhunta sokubumba lapho sithola imidwebo yekhasimende noma amasampula, bese sikhiqiza isikhunta ngokulandela ukwakheka kwesikhunta.Isikhunta ngokuvamile zihlanganisa forging dies, ukunquma uyafa.

Ukusika nokushisa kwe-billet yensimbi

Imvamisa, sizolungisa izinto ezisetshenziswa njalo esitokweni esinempahla engu-No. isithando somlilo sizosetshenziselwa ukushisisa izinto ezingavuthiwe ekushiseni okuthile futhi ekugcineni kubekwe induku yokudla ohlakeni lwensimbi lokubumba.

Ukuqamba

Ngaphambi kokuthi inqubo yokubumba insimbi iqale, okungaphezulu nangaphansi kuyafa kuzoxhunywa ku-anvil block yomshini wokukhanga.Khona-ke izisebenzi zizokhetha izinto zensimbi futhi zizibeke phakathi kwe-forging dies ukuze zifinyelele isimo esifisa ngokucindezela izinto zensimbi izikhathi eziningana ngesivinini esikhulu.

Ukuhlanza

Ngemuva kokuqedwa kokubumba, kuzoba nama-burrs angafuneki azungeze izikhala ezimboziwe, ngakho ukususa ama-burrs kuyisinyathelo esidingekayo.Okudinga ukuthi abasebenzi bafake i-trimming dies ngaphansi komshini wokubhoboza, bese becindezela izikhala ezimboziwe ukuze bahlanze ama-burrs ebusweni be-forging.

Ukwelashwa kokushisa

Inqubo yokwelapha ukushisa isiza ukuthola ukusebenza kwemishini okudingekayo kanye nobulukhuni bemikhiqizo.Izindlela zokwelapha ukushisa zihlanganisa normalizing, quenching, annealing, tempering, ukuqina nokunye.

Ukuqhuma kwesibhamu

Ngemuva kwenqubo yokudubula, ama-forging azoba nendawo ebushelelezi futhi ehlanzekile kunalokho obekungaba njalo.Ngokuvamile ubushelelezi obungaphezulu be-forging butholakala ku-Ra6.3, ebushelelezi nakakhulu kunaleyo yokusakazwa kwe-wax elahlekile.

Iyacubungula

Kwezinye izingxenye, inqubo yokubumba ayitholakali ekubekezeleleni okudingekayo, ngaphansi kwalokhu, ukucubungula kuyakhethwa.Sizokwenza ukucubungula komkhiqizo ngemishini yokucubungula ehlukene, okuhlanganisa umshini wokugaya, umshini oyisicefe, umshini wokubhoboza, umshini wokugaya, umshini wokulawula izinombolo njll.

Ukwelashwa kwendawo

Ezimweni eziningi, uma kungekho zidingo eziqondile ezidingekayo, sizoba nokwelashwa kokuvikela ukugqwala kwamanzi/amafutha endaweni yokufogetha.Singakwazi futhi ukwenza ezinye izindlela zokwelapha ezingaphezulu, okuhlanganisa ukufutha ngopende, ukugcotshwa kwempushana, i-electroplating, i-electrocoating ukuze kuhlangatshezwane nezidingo ezithile zamakhasimende ethu.

Ukuhlolwa kokugcina

Sizoba nokuhlolwa kosayizi womkhiqizo ukuze siqinisekise izinga eliphezulu lemikhiqizo yethu.Kwesinye isikhathi, siphinde sibe nokusebenza kwemishini kanye nokuhlolwa kwezingxenye zamakhemikhali emikhiqizweni yethu.

Iphakheji nokulethwa

Ezimweni eziningi, izingxenye ezifojiwe zizopakishwa ezikhwameni ze-polyethylene bese zifakwa emabhokisini okhuni aqinile.Siyakwazi futhi ukwenza amaphakheji ngendlela oyifisayo ngokwezidingo zekhasimende.Njengoba sitholakala epaki yezimboni yaseRuian forgings, sifinyelela kalula ekunikezeni izinto zokusetshenziswa, okuyizindleko ezisebenza kahle kukho konke.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu